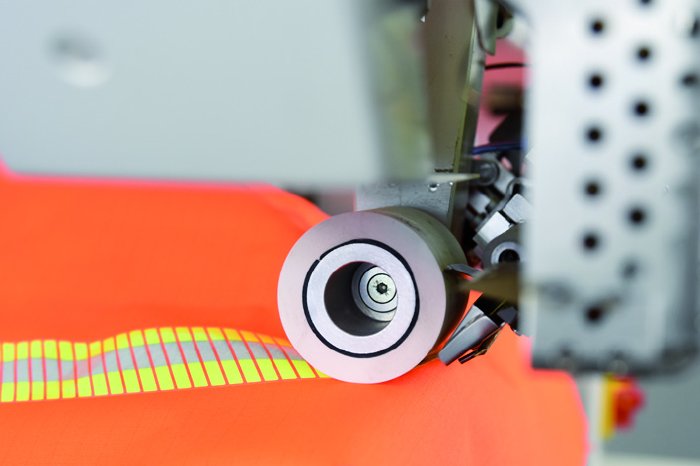

With the new machines, the lengths may be exactly programmed; it is possible to program individual segments and complete processes. The new tape cutter ensures a flush beginning and end of the strip with a straight cut.

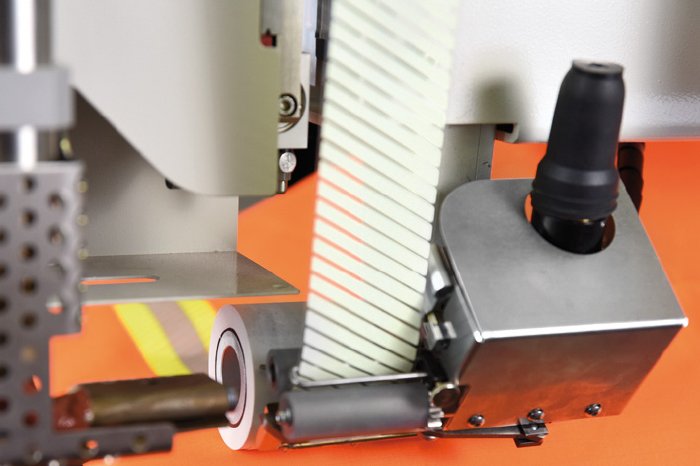

The modern touch screen ensures the intuitive operation via pictograms. It enables the specification of various password-protected user levels. Due to this feature parameters defined by the production planners cannot be modified by the operator thus significantly increasing process reliability. Basically, programs and parameters may be transferred to additional machines in the production process.

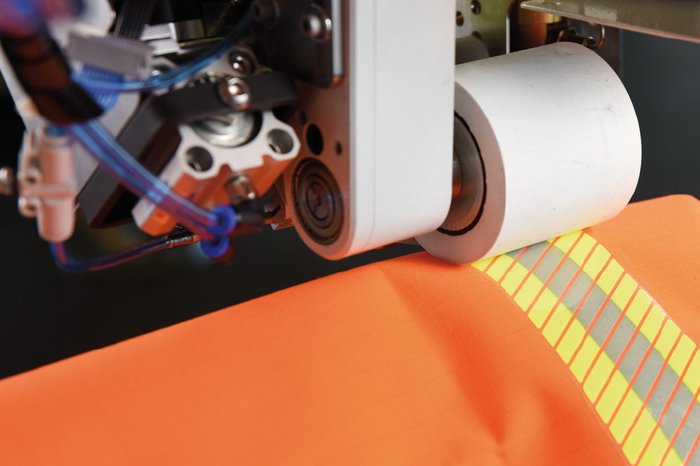

Those responsible at PFAFF are confident that important manufacturers will switch from sewing to hot-air tape welding.