PFAFF INDUSTRIAL, manufacturer of sewing and welding machines, has two tape-welding machines in its portfolio to use on water-repellent, waterproof and breathable materials which ensure high process-reliability and reproducible quality: the PFAFF 8303i (Flat-bed machine) and the PFAFF 8323 (Cylinder-arm machine). The machine is used for the programmed sealing of sewn or welded (e. g. ultrasonic) seams. The machines may also be used for cross seams in 3-layer areas.

The PFAFF-solutions embody 30 years of know-how and experience. In 1987 PFAFF introduced the first hot-air tape-welding machine. The latest generation of these machines is equipped with some technical features which are considered industry hallmarks in terms of quality, performance and process reliability:

Dynamic welding:

Automatic adjustment of the heating power to the variable speed (Option on 8303i). Automatic monitoring and adjustment of all pre-set or programmed parameters.

Programmed welding:

All relevant process parameters can be programmed and saved via touchscreen. Both individual segments and complete cycles can be programmed (Option on 8303i)

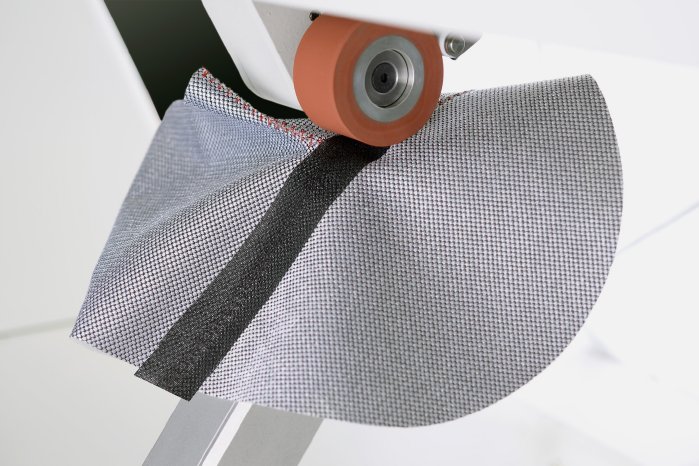

Differential feed:

Two separate drive motors for the top and bottom feed roller guarantee an optimum adaptation to the operation (e.g. smooth seams or fullness for formed parts).

Tape cutter with separate drive:

Trimming of the seam tape becomes unnecessary (welding from the beginning of the tape), resulting in a considerable reduction of the tape used. The tape cutter is electronically controlled, with precision adjustment for an exact setting.

At the A+A trade show in Düsseldorf PFAFF INDUSTRIAL will show a special version of the PFAFF 8323 to weld reflecting stripes that are 50 mm wide onto jackets, work clothes etc. Additionally, various sewing solutions will be on display in hall 11/B25 where PFAFF INDUSTRIAL and Dürkopp Adler will jointly present themselves.