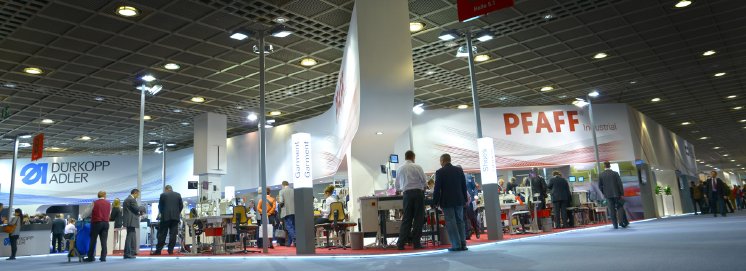

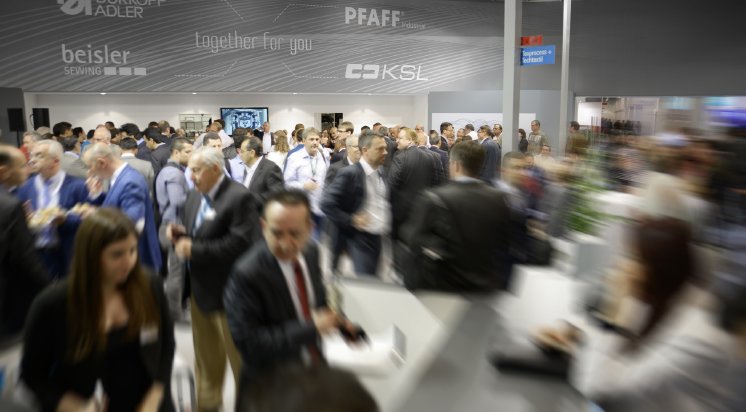

At an architectually impressive joint stand covering more than 1,000 sqm in the entire front section of Hall 5.1 Dürkopp Adler AG and PFAFF Industriesysteme und Maschinen GmbH with Beisler and KSL showcased 110 industrial sewing and welding solutions. More than 300 sales partners from around the world used this joint platform to present the multitude of powerful solutions of the Shanggong-group companies to thousands of visitors every day.

PFAFF INDUSTRIAL managed to appeal to and wow visitors of the TEXPROCESS and TECHTEXTIL alike with the products they presented. For the first time ever almost the entire line of welding machines was shown in Frankfurt.

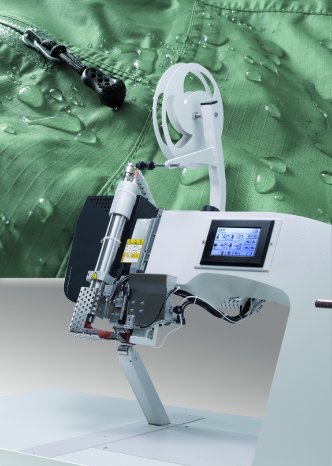

Highlight in that segment was the newly developed PFAFF 8303i tape-sealing machine for the programmable sealing of seams. The new PFAFF 8303i stands for "simple and innovative". The process-reliability and repeatability in the 8303i was greatly increased. The use of a differential feed provides the customer with top seaming quality. All relevant process parameters may be programmed and saved via touchscreen. The new PFAFF 8303i allows for up to 20 % more productivity versus other tape-sealing machines. This innovation underscores PFAFF INDUSTRIAL'S innovation leadership in welding.

In the sewing machine sector the PFAFF-products were divided into the segments "garment", "industrial", "shoes" and "jeans". Several new products in the jeans-segment which is to be greatly expanded as part of the group's strategy were shown in Frankfurt. The PFAFF 3840 is a high-performance and highly flexible machine to attach belt loops. Among the new machines were two PFAFF 3538 pocket hemmers as well as two versions of an automat to attach waistbands (PFAFF 3819).

The PFAFF 3586-24/02 is an automatic sewing unit for long darts (490 mm). It may for example be used for darts on slim-line shirts and blouses.

Visitors from the shoe and leather industry got a look at mechanical and electronic high-speed post-bed seamers (newly designed) and large-area solutions for complex decorative and assembly seams. With 1,200 x 700 mm the PFAFF Portal featured the biggest sewing area of the three large area sewing units from PFAFF INDUSTRIAL shown in Frankfurt.

The group is particularly proud of the Texprocess Innovation Award that was won for the Dürkopp Adler M-Type Premium in combination with M2M. M2M is an intelligent machine and production monitoring system that enables the operator to call up all data anywhere and at one glance. In the future M2M may be used to connect PFAFF-machines to the new P40CD-control.

After the trade show is before the trade show - the group is already looking forward to making just as strong an appearance in Asia at the CISMA in September 2015.