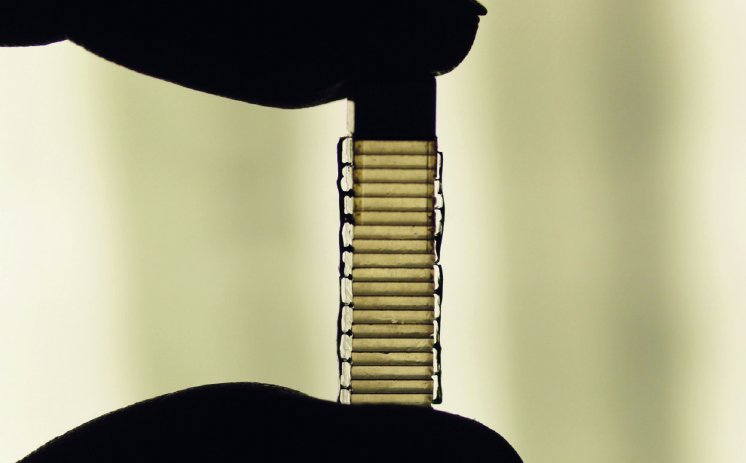

In contrast to the classic piezo actuator made of lead zirconate-lead titanate (PZ), Picoactuators show a high degree of linear displacement. In real numbers that is: ten-times higher linearity with ten-times lower displacement is what makes Picoactuators a "neat little package". Picoactuators are configurable up to heights of 20 mm and maximum travel of +/-3 µm.

Fields of application are in the precision positioning technology if the small displacement is enough and at the same time high dynamics and accuracy (linearity) is required. The high linearity means the actuators can be operated without position control, which can improve the dynamics and system bandwidth by up to one order of magnitude.

Application examples are probe scanners in atomic force microscopy with more than 100 Hz scanning frequency. High-resolution microscopy also provides another application, where conventional piezo scanners with a vertical axis are equipped with picoactuators to reduce deviations from the planar scan to below 1 nanometer in the Z axis.

Since 1992, PI Ceramic (PIC) has been developing and manufacturing piezo ceramic materials and components for standard and OEM solutions: piezo components, ultrasonic transducers, actuators and system solutions. The PICMA® multilayer actuator technology, which received an award for its reliability, is one of many inventions of PIC. PI Ceramic, a subsidiary of Physik Instrumente (PI), is located in the city of Lederhose, Thuringia, Germany.