The new composites offer an alternative to the well-known all-ceramic components. In addition to excellent adaptability to specific shapes, the polymer content offers many other advantages over all-ceramics. For example, composites can easily adapt to environments with different acoustic impedances. This enables a wide range of applications in the area of medical technology, for example, in high-intensity focused ultrasound (HIFU) applications or for diagnostic imaging, as well as in industrial applications such as flow rate metering or non-destructive measurement. By suppressing cross contraction and the associated vibration modes, the composites also enable improved focusability, sensitivity, and resolution.

Different Filling Polymers

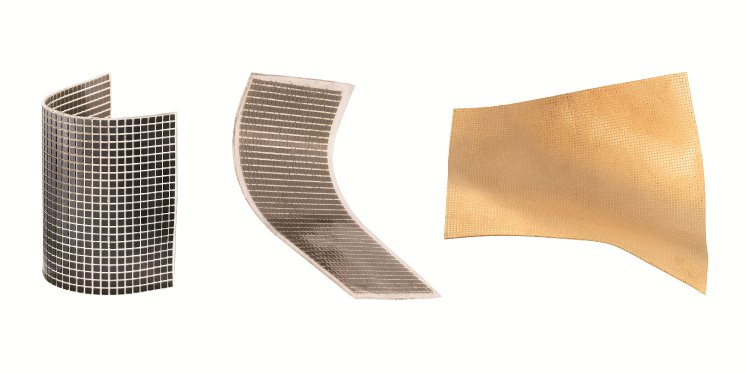

To enable the best possible adaptation to the respective application, PI Ceramic offers two different types of filling polymers for prototype development: Epoxy resins are used for rigid composites, while softer, silicone-free polymers are available for highly flexible composite structures.

Various Arrangements, Electrodes and Contacting

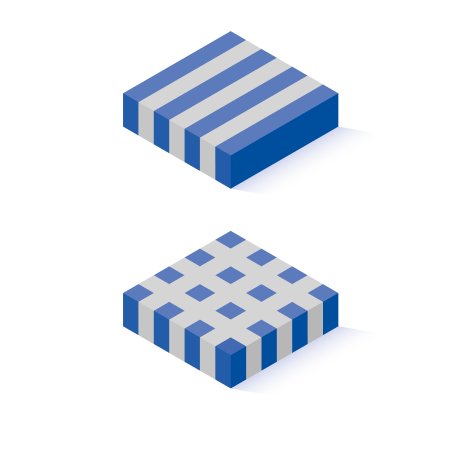

In addition to the actual manufacturing of piezoceramic composites in ceramic rows (2-2 arrangement) or individual pins (1-3 arrangement), PI Ceramic also has the capability to apply full-surface electrodes or insulated single electrodes using thin-film technology. The composites can also be supplied with stranded wires or flexible circuit boards bonded to them.

PI Ceramic in Brief

Redefining the limits of what can be measured and moved, together with our customers: As a worldwide partner with over thirty years of expertise, PI Ceramic develops and manufactures piezoceramic components and subsystems for applications in the areas of medical technology, industrial ultrasonic sensors, and precision dosing. At the site in Lederhose (Germany), one hundred employees out of the current total of more than 400 are engineers. PI Ceramic is part of the PI Group, the innovation and market leader in high-precision positioning technology.