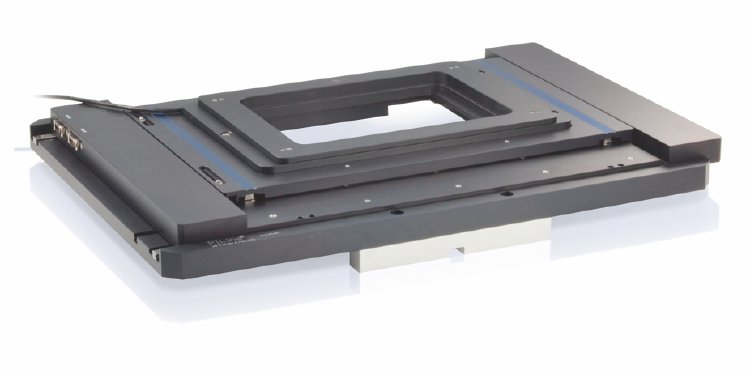

The stage is driven by a PILine® piezoceramic linear motor which, in contrast to flanged stepper or DC motors with large lead screw ducts, is integrated inside the stage and does therefore not require any additional installation space. This facilitates the integration of the stage under the microscope and offers an unhindered access to the specimen. The PILine® motors transmit the force directly to the moving platform and thus keep the position stable, even when powered down. Thereby, they do not generate additional heat.

M-687 stages provide maximum closed-loop velocities of up to 250 mm/s. Their settling behavior is optimized, i.e. settling takes place within a few miliseconds. On the other hand, a slow movement is also of importance for users: Even if a distance of only a few micrometers per second is covered, the movement can still be observed under the microscope at 1000-fold magnification.

By combining a PILine® drive with a high-resolution position sensor, a stiff and high-precision stage has been designed which can reach positions repeatedly with sub-micron accuracy. This is particularly useful for imaging methods such as tiling and stitching which are required for large specimen.

Well-known for its high quality, PI has been one of the leading players in the global market for precision positioning technology for many years. PI has been developing and manufacturing standard and OEM products with piezo or motor drives for 40 years now. In addition to its three German factories, PI has eight subsidiaries and a total of over 500 employees worldwide.