Pi4_robotics GmbH, the German EL inspection specialist wouldn't longer put up with detecting and counting defects and has developed the pi4_power loss estimation tool which is part of the fully automated EL inspection systems since the beginning of 2013.

This tool is able to decide which defects may cause power loss of the module during life time and which defects will not cause much loss of power ever. Especially cracks parallel to the bus bars tend to isolate cell areas(example), whereas cracks parallel to grid fingers will not interrupt current flow to the bus bars.

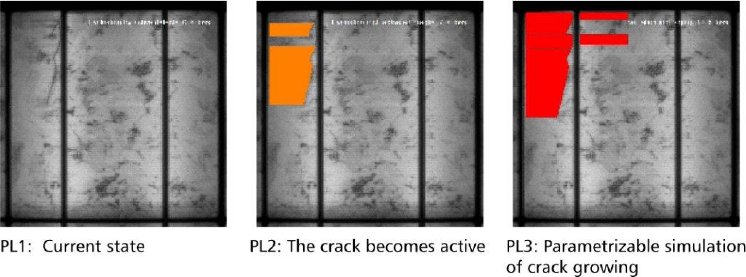

Pi4 EL Power Loss Estimation is easy to parametrize and works in three steps:

EL Power Loss 1 - capture the current state of power loss

EL Power Loss 2 - Power loss estimation with cell aged, micro cracks turned into active cracks

EL Power Loss 3 - Power loss estimation with cell aged, crack and grid finger error growth assumed

The gradual determination of inactive areas in multi- and mono crystalline pv modules enables the conclusion on current state and above all on power loss to be expected in future. Precondition for all is the reliable automated detection of defects which pi4 has introduced in the market since years.