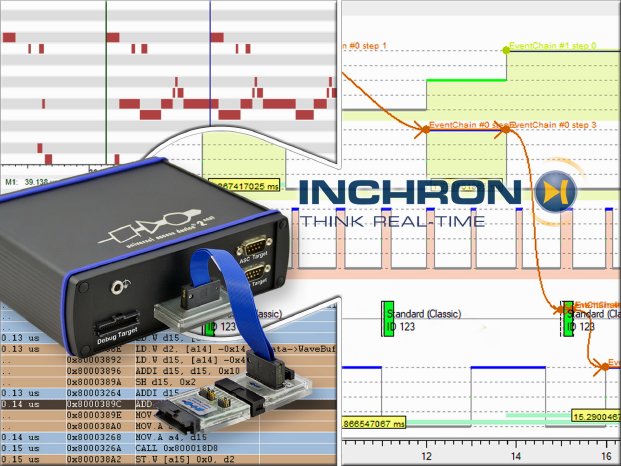

At first, PLS’s Universal Debug Engine® (UDE) records large amounts of trace data at run-time directly from the control unit and preprocesses them. For this purpose, the UAD2next and UAD3+ access devices from the Universal Access Device (UAD) family are available to the user. They support all common trace interfaces using appropriate target-specific trace modules. Depending on the model variant, between 512 MB and 4 GB of trace data can be stored.

Using chronVIEW from INCHRON, the recorded trace data is then visualized in many ways. Dependencies between parallel sequences of control algorithms that have a negative effect on real-time behavior can thus be easily detected. At the same time, the tool automatically checks compliance with real-time requirements. This provides users with a quick, comprehensive and clear insight into the timing of the complete system.

Being able to investigate the scheduling of single-/multi-/many-core systems with different operating systems and communication interfaces is an important basis for eliminating errors. By combining the two tools, an analysis can now be performed fully automatically in the context of comprehensive development and test workflows. Users can therefore continuously check the time behavior of their system and thus ensure that any problems that may occur are resolved at an early stage of the project. This significantly reduces the risk of later surprises, more time-consuming reworks and high additional costs.

“For highly complex systems, rapid detection and correction of errors is one of the most important prerequisites for an efficient development process,” says Dr. Ralf Münzenberger, CEO of INCHRON GmbH. Jens Braunes, Product Manager at PLS, adds: “Our joint solution package gives developers all the necessary prerequisites for this. The use of run-time information from the real control unit under field conditions delivers reliable statements about the timing behavior and is therefore indispensable for error analysis and elimination.”

INCHRON GmbH

INCHRON is the world-wide leading provider of solutions for architecture, design, and automated optimization of real-time systems with regards to timing behavior and performance. Our solutions cover the whole range from single-core to multi-core to multi-CPU to distributed systems. Well-known OEMs and tier suppliers world-wide rely on INCHRON’s methods and tools. Our solutions are used successfully in industries such as automotive, automation, avionics, defense, healthcare, mobile and M2M/IoT, covering all phases of the development lifecycle. Since INCHRON was founded in 2003, our consulting team has made significant contributions to more than 160 successful customer projects.

The INCHRON Tool-Suite provides powerful tools, covering simulation, worst-case analysis, automated optimization, and comprehensive visualization and analysis of traces. The Tool-Suite covers all important steps to focus on event chains.

Read more on www.inchron.com.