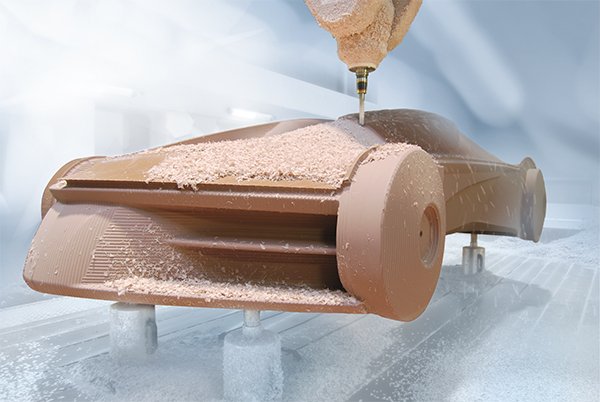

RAMPF RAKU® TOOL Close Contour pastes and castings stand for the manufacture of high-performance models and molds that are already close to the shape of the final part. The benefits:

- Minimal material usage

- Minimal production waste

- Extremely fast milling

- First-class, seamless, and very fine surfaces without bonding lines

The two-component, thixotropic epoxy systems are applied to a close-contour shape supporting structure with a mixing and dispensing machine, cured, and then CNC machined according to customer CAD data; almost any kind of supporting structure can be used, including RAKU® TOOL SB-0080 styling board, EPS, and cast aluminum.

RAKU® TOOL Close Contour pastes exhibit outstanding dimensional stability and enable quick and easy processing with no slump on vertical surfaces and smooth overhead dispensing. Applications include design and styling models, molds, large-scale modeling, rotor blade, wind turbine, and boat models. RAMPF offers a paste application service and the comprehensive technical support of experienced engineers.

Close Contour Castings

The semi-finished polyurethane systems are supplied as a three-dimensional casting. The monolithic, close-contour block with even wall thickness is manufactured in-house at RAMPF based on customer CAD data.

The cavity is milled into a lightweight mold material such as EPS or RAKU® TOOL SB-0080 styling board. Following the application of the release agent, the cavity is filled using a special casting process. Milling is quick and easy. Applications include styling, design, master, cubing, and data control models.

SAMPE 2023 product feature – Close Contour Casting RAKU® TOOL CC-6503

Visitors to the RAMPF booth can see for themselves the high quality which is achieved by using RAMPF Close Contour Castings. Using RAKU® TOOL CC-6503, Symmetrix Composite Tooling, a full-service composite tooling manufacturer of complex and innovative designs based in Bristol, R.I., produced a lightweight sphere with first-class surfaces.

RAKU® TOOL CC-6503 has a very dense, homogeneous, and fine surface; can be easily machined; used for the manufacture of bath models for electroforming, lay-up tools, RIM tools, and many more.

Lightweight solutions for ultra-strong composite parts

A further highlight at the RAMPF booth – cutting-edge solutions for automated composite manufacturing. RAMPF Composite Solutions based in Burlington, Ontario, Canada, designs and manufactures some of the world’s most complex lightweight composite products for the aerospace, defense, industrial, medical, high-end consumer, and green transportation industries – from sketch to qualification.

The company combines

- Low-cost tooling and fixtures

- High-performance structural resins

- Structural optimization via Tailored Fiber Placement (TFP) Technology

Visit RAMPF Group, Inc. and Symmetrix Composite Tooling at SAMPE 2023 – Booth G24!