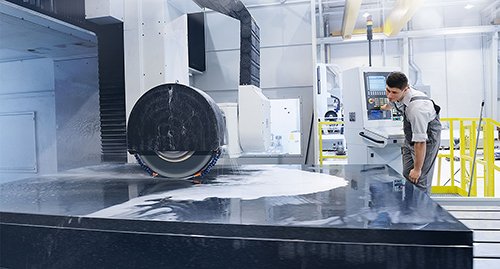

The Precision Grinding Center offers an end-to-end service concept for the contract grinding of high-precision machine components. State-of-the-art equipment and a fully climate-controlled production hall ensure highest quality and fast delivery.

Wolfgang Goldmann, Head of Precision Manufacturing at RAMPF Machine Systems – “We are very proud of this achievement. Since it was founded in 2010, the grinding center has established itself as a strong, innovative, and reliable partner to industry. We look forward to processing the next 10,000 machine components.”

With a production area of 2,100 m² and a three-shift-operation, the RAMPF team of experts offer a comprehensive service for all aspects of high-precision flat grinding and guideway grinding. This includes:

- Grinding of mineral casting, hard stone, ultra-high performance concrete, ceramics, gray cast iron, and steel up to 7,000 × 2,650 × 2,000 mm (L × W × H) and 25,000 kg

- Technical and design advice

- Hand lapping of components with high-precision requirements

- Measurement and documentation of accuracies in the µm range at fully air-conditioned measuring stations (+/- 0.5 C° annual deviation) using autocollimators, electronic inclination scales, and laser interferometers

- Holistic manufacture of precise and dynamic moving systems and basic machinery, including joining (bonding, bolting)

- Precision assembly of add-on components such as guideways, measuring systems, and drives

More information