Key facts

- RAMPF offers premium contract manufacturing services for sealing, casting, and bonding across wide range of applications in the automotive, electronics, energy technology, household appliance, lighting, and medical technology industries.

- RAMPF develops and manufactures reactive plastic systems based on polyurethane, epoxy, and silicone, including liquid and thixotropic foam gaskets, electro casting resins, and adhesive systems.

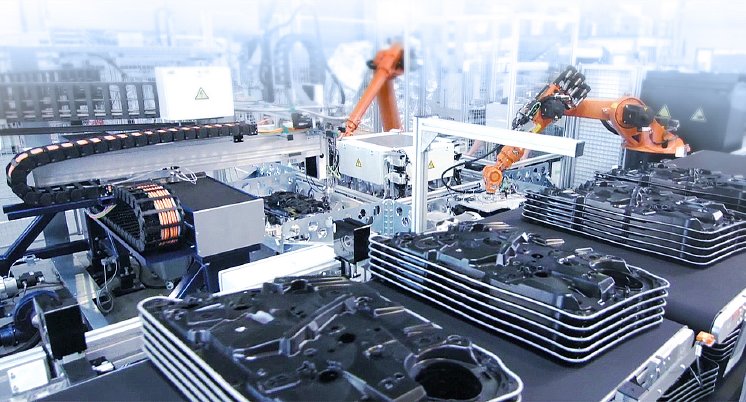

- RAMPF is an international market leader in automated mixing and dispensing systems for sealing, casting, and bonding one- and multi-component reactive plastic systems.

- RAMPF offers tailor-made Formed In Place Gaskets (FIPG) and Formed In Place Foam Gaskets (FIPFG) made from polyurethane, utilizing advanced high-speed-robotic CNC dispensing. The reactive plastic systems are applied directly to components, expanding in situ for rapid bonding and significantly reducing cycle times and enhancing overall efficiency.

- High-performance, application-specific polyurethane seals designed to withstand extreme pressures and temperatures, featuring exceptional chemical resistance.

RAMPF processes reactive, thermally, and electrically conductive polymers with premium mixing and dispensing systems, ensuring precise and rapid handling of these highly filled materials.

The resulting parts provide reliable protection against contact, moisture, and damage, ensuring high-performance and long-lasting functionality of electronic assemblies.

Bonding

RAMPF processes multi-component adhesives into precisely reacting products for component joining, with optional pre-treatment to enhance adhesion. This high precision joining process can be performed manually or fully automated.

Integrated curing-on-demand (COD) systems speed up the curing process, while vacuum joining eliminates air bubbles for applications like optical bonding in displays.

Unmatched quality and efficiency

The quality and efficiency of RAMPF’s contract manufacturing services are unparalleled, as the company is both a market-leading specialist for

- Reactive resin systems based on polyurethane, epoxy, and silicone, including liquid and thixotropic sealing systems, electro casting resins, and adhesive systems.

- Automated production systems with integrated dispensing technology for sealing, casting, and bonding reactive resin systems.