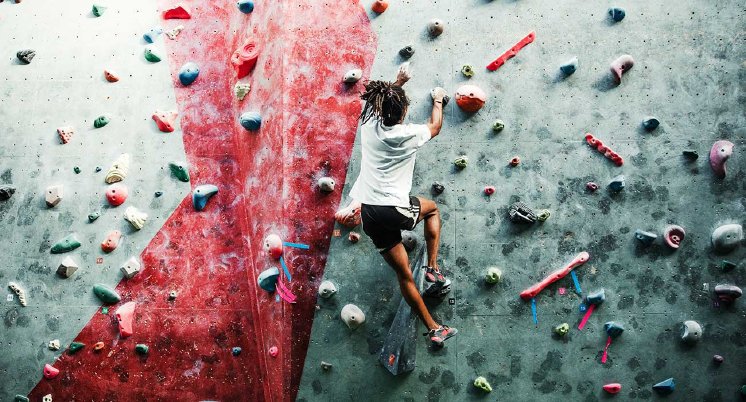

RAKU® TOOL IE-3092 is the ideal choice for climbing hold production as it enables customers to create their own grips easily and efficiently without having to outsource to a manufacturer.

The polyurethane system is easy to process both by hand-batching and automated meter-mix processes. It is poured into a silicone mold and then cured in an oven.

The low-viscosity liquid casting compound features

- Excellent abrasion and impact resistance

- Very fine surface structure

- High molding accuracy

- Long pot life

RAMPF Group, Inc. also carries an extensive line of pigments, mold releases, and molding silicone rubber needed to satisfy all requirements for creating molds and casting holds.

Visit RAMPF Group, Inc. at Climbing Wall Summit 2023 in Pittsburgh, PA, from May 17 to 19 – Booth 201!