Key facts

1. Streamline Automation, a leader in 3D CNC fabrication systems, has partnered with RAMPF, the world's largest tooling board producer, to create a highly detailed model of a Corinthian capital.

2. RAMPF’s high-performance polyurethane styling board RAKU® TOOL SB-0096 is easy to shape, has a very good surface quality, and exhibits good resistance to heat and organic solvents.

3. Streamline Automation’s powerful 4-axis CNC router FROGMILL™ combines industrial strength, quality, and precision to create large, intricate pieces.

“From vision to reality.”

This is the standard which Streamline Automation has set itself – and the reason the company has pioneered the automated 3D CNC carving market with its FROG3D® family of products. The turnkey, completely integrated, and fully automated CNC solutions are used around the globe to create spectacular creations.

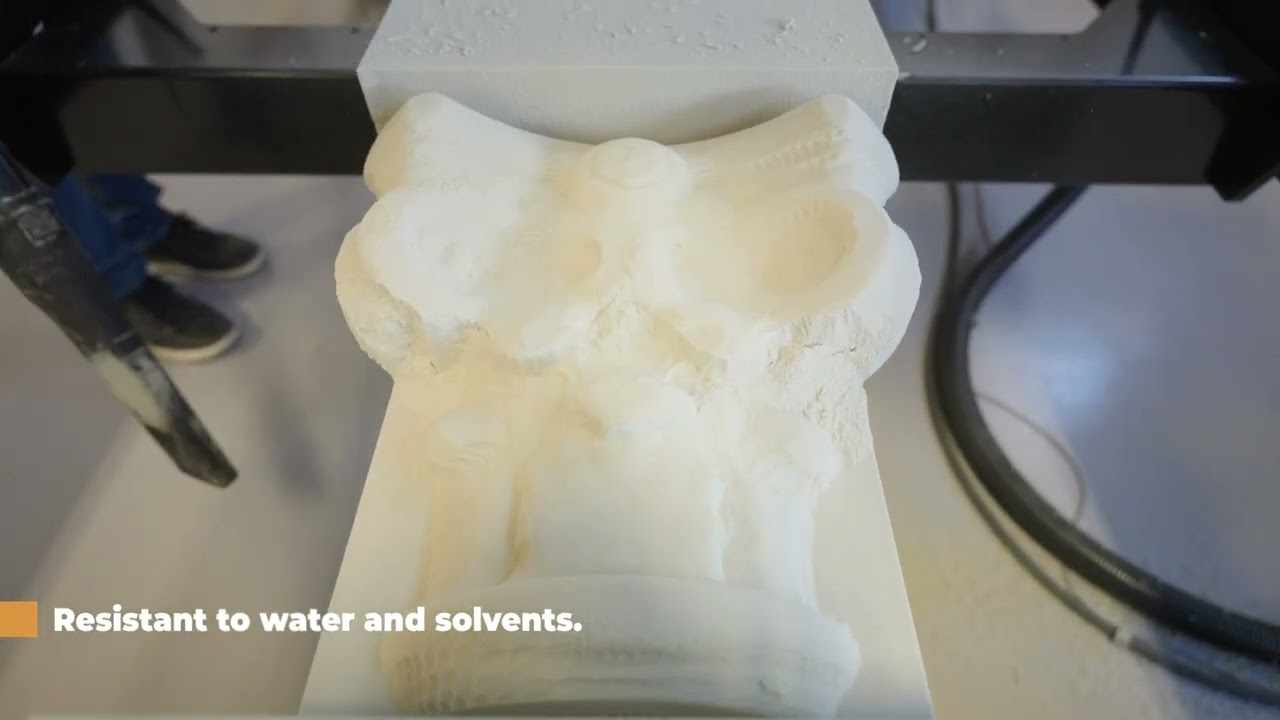

A truly amazing and stand-out product was recently manufactured using Streamline Automation’s state-of-art CNC foam milling solution FROGMILL™ and RAMPF’s polyurethane board RAKU® TOOL SB-0096. The Corinthian capital made from RAKU® TOOL SB-0096 and milled by the FROGMILL™ CNC router features an extremely high level of detail.

RAKU® TOOL SB-0096 – the go-to board for styling and design

RAMPF’s high-performance polyurethane board RAKU® TOOL SB-0096 is used in several industries for design studies, program proving, substructures for Close Contour paste, and negative molds for casting, amongst others. The exceptionally light board can be easily shaped, has a very good surface quality, and exhibits good resistance to heat and organic solvents.

FROGMILL™ – the most powerful 4-axis CNC router available

Streamline Automation’s 4-axis CNC router FROGMILL™ combines industrial strength, unequalled quality, and highest precision to create large and intricate pieces. The fourth axis offers index cutting capabilities to create full 3D carvings from a single piece. FROGMill™ creates production efficiencies and also provides the necessary accuracy and detail to create stunningly detailed projects.

Norm Eaton, President at Streamline Automation – “We collaborate closely with our clients to elevate their production processes, products, and businesses to new heights. Our success is defined by their success. As an artist, fabricator, or designer, you aspire to create art without limitations imposed by materials, technology, or cost. The collaboration with RAMPF is a prime example of how this ideal can be achieved.”

Nathan Jacobs, Regional Sales Manager at RAMPF Group, Inc. – “Model builders can push design boundaries like never before, thanks to Streamline Automation’s state-of-the-art 3D machining technology combined with our premium polyurethane board. This powerful machine and material synergy allows for unparalleled precision, creativity, and efficiency in model creation. We are excited to present the outcome of our collaboration with the Streamline Automation team at IAAPA in Orlando, Florida, from November 19 to 22.”

About FROG3D® by Streamline Automation

FROG3D® offers advanced 3D fabrication solutions to address diverse production challenges. The turnkey 3D CNC fabrication system is designed to enable the creation of larger, higher-quality projects with greater efficiency. Featuring cutting-edge technology, commercial-grade construction, and industry-leading training and support, FROG3D® seamlessly bridges the gap between creative vision and production needs.

From the initial design to the final product, FROG3D® provides intelligent and intuitive solutions for every stage of the fabrication process. The comprehensive suite of tools – including 3D scanning, digital modeling, hot wire foam cutting, 3D CNC milling, and coating application – has been meticulously engineered to meet the precise needs of dedicated professionals.