For example, the efficiency of the REIcofeed 2.1 coextrusion feedblock allowing for an optimal adjustment during running production of the films/sheets composed of up to eleven or more individual layers could still be drastically improved by the integration of a new small element which allows the encapsulation of a multi-layer film/sheet inside the feedblock to avoid the need of an additional encapsulation device in the flat die and the use of an additional extruder. Reifenhäuser CSC will be showcasing this new REIcofeed 2.2 model type at K 2016.

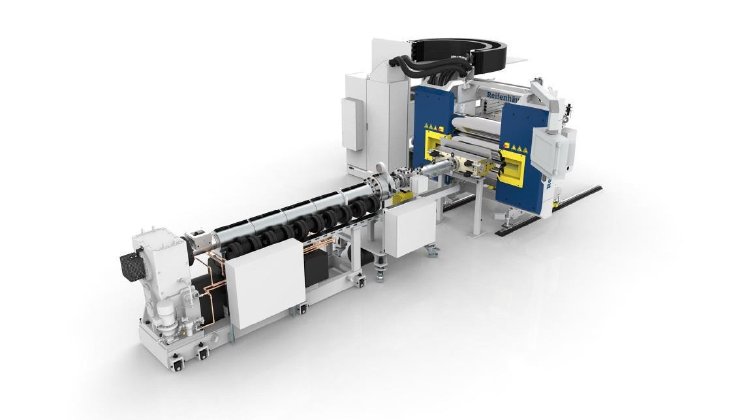

Another example are the new MIREX-MT polishing stacks with the patented mechatronic nip adjusting system. The overwhelming success of the MIREX- MT-V-AX high performance design series presented at K 2013, which allows for example the production of PET films of less than 150 µm thickness and with an output of more than 2.5 t/h thanks to large roll diameters and the optional axis-crossing, has led to the installation of this innovative nip adjusting system in all Reifenhäuser polishing stack model types. MIREX-MT-HI, the smallest one with 310 mm roll diameter, will be demonstrated as key component of a new generation of in-line thermoforming sheet lines in production. This line, in combination with a high-speed extruder with the lowest space requirement in the market, satisfies the demands of the market for highest efficiency and smallest possible footprint.

At K in Düsseldorf, hall 17 stand C 22, a polishing stack of the MIREX-MT-H model type will be showcased for the production of PS/PP sheets off-line, that means without a directly connected thermoforming machine.