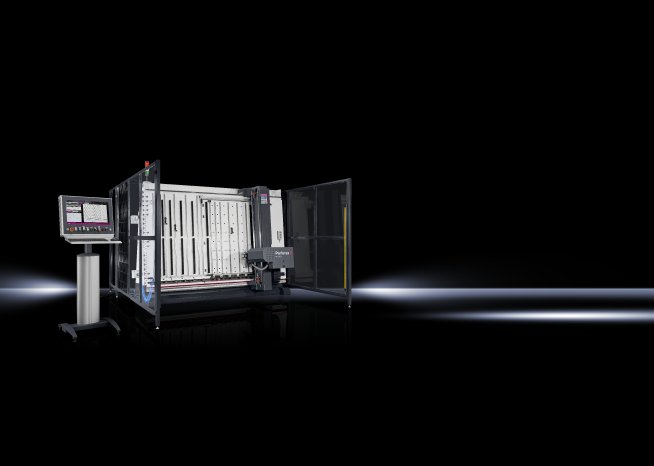

- The new Perforex MT milling centre: optimised mechanics and digital integration

- The new RiPanel Processing Center: Interface from engineering to machine controllers with efficient job management

- New financing models and consulting for individual optimisation steps in switchgear manufacturing

The next level for greater efficiency and precision

In continuing its development of the Perforex, Rittal has incorporated the practical experience gained through exchanges with customers. This has led to numerous technical improvements that will help customers in their day-to-day work. There is also an operating concept that is tailored to perfect interaction with the software solutions from Eplan and Rittal.

One example is the integrated swarf suction extraction feature directly on the spindle, which, together with a new floor seal, reduces the effort needed for cleaning. Moreover, new workpieces can now be retrofitted much more quickly. The new automatic tool measurement feature checks the length of the current tool and automatically transfers the parameters to the machine controls. It also detects any tool breaks, which results in fewer outages and an overall higher level of productivity. The patented pressure plate reduces vibrations, leading to a longer tool life, higher cutting speeds and better cut edges. New light barriers and light curtains ensure safety.

The use of the new generation of Perforex MT machines greatly improves efficiency in the workshop by as much as 85% compared to manual machining.

From engineering to a machine order at the touch of a button

One vital lever for increasing efficiency is to integrate the machines into the digitised processes. The new RiPanel Processing Center optimises the interface, from engineering to machine controllers. Design data from Eplan Pro Panel and information such as quantity and the target date are transferred directly and converted into machine jobs. The integrated order management tool helps improve interaction between several machines. “For customers, it means that they cut lead times, error rates and costs, while making their workshop processes fit for the future,” summarised Mr. Schell.

A clear path for investment

The current economic situation is also affecting control and switchgear manufacturers. “They can take advantage of the challenge by seeing it as an opportunity to gain competitive advantages with the right automation steps,” says Rolf-Günther von Kiesling, Head of Business Unit Rittal Automation Systems: “We not only support our customers by advising on the question of using the right machine technology, but also in making investment decisions through new financing models.”

Rittal is launching a new financing program for customers. The first step will be linear financing via supplier credit in the second quarter of this year. "We want to lower the hurdles for investments so that control and switchgear manufacturers can more easily tackle their automation steps," says von Kiesling: "With the right installment financing directly from Rittal, they immediately benefit from the efficiency of their new machine and skip the investment procedure involving a bank."