The popularity of LED lighting has made translucent plastics increasingly important for luminaire covers. The covers are used to diffuse the light emitted by the point-shaped luminaires as uniformly as possible, making the point-shaped light sources (hot spots) invisible by high light diffusion. At the same time, the user naturally wants the highest possible luminous efficacy.

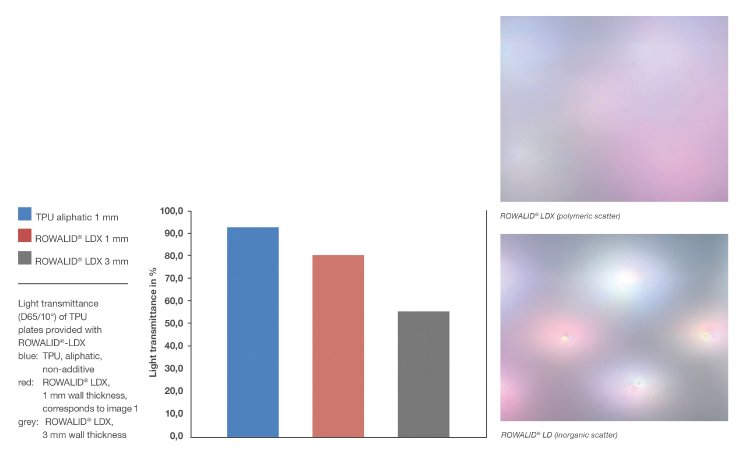

The use of suitable materials can save on the number of luminaires and energy. With ROWALID® LDX masterbatches, components can be uniformly illuminated with a silky matt finish at maximum luminous efficacy without the hot spots shining through.

ROWA Masterbatch has so far successfully provided ROWALID® LD and ROWALID® LDX products for hard plastics such as polycarbonate, polymethylmethacrylate and polystyrene. New additions to the portfolio are ROWALID® LD and ROWALID® LDX products for thermoplastic polyurethanes (TPU). The flexibility of these soft thermoplastic elastomers enables new applications in lighting design.