As is well known, continuous production processes are influenced by many different factors that directly affect the quality of both the process and the product. Many manufacturers try to monitor the process by taking random samples. The ideal solution, however, would be a continuous stream of information on the process quality - from the start-up phase to colour adjustment to processing and finally the purging step. The ColVisTec Inline System supplies all this information in real-time, especially for extrusion applications.

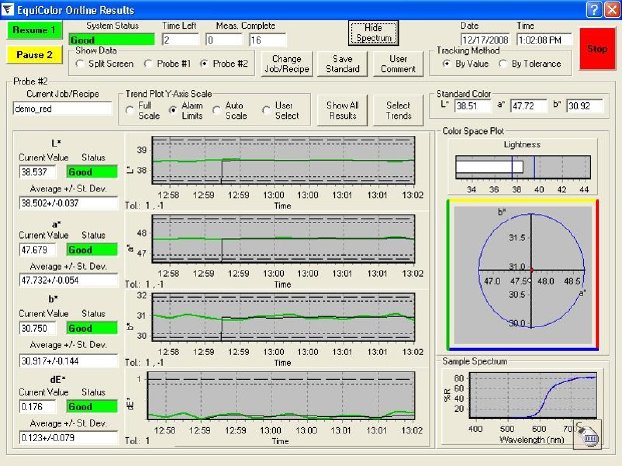

The Inline System for process monitoring comprises an industrial-grade spectrophotometer, fibre optics probes designed for extrusion processes, user-friendly software for evaluation and display of the captured data as well as a number of industrial interfaces to transfer the data to the customer-owned IT systems. The measuring point and electronics can be up to 20 metres apart. The system can simultaneously monitor two measuring points (i.e. extruders). There are no active electronics in the vicinity of the measuring point. The system's measuring probe has a 1/2" 20UNF thread with a standard pressure sensor bore that can be installed on the extrusion die. It leads light from the photometer to the plastic melt where it is reflected and sent back to the photometer. This simple arrangement captures the measured colour values, e.g. in L*a*b* format, at intervals of 1 second. Since the colour values of the melt correlate with those of the finished part, the system can determine whether compliant goods are being produced during processing. Because variations in the process and raw materials affect the colour values, the system provides comprehensive process control and sends an alarm as soon as a defined threshold value with respect to the reference is exceeded.

The inline colour spectrometer from ColVisTec is a perfect complement to ROWASOL liquid colours and enables the highest possible productivity. It can also be used in combination with the ROWASOL RAINBOW System for inline monitoring of the purging step during a colour change. Any corrections of the colour recipe can be carried out online with the RAINBOW System and the result is shown immediately on the monitor of the inline spectrophotometer.

###

Text approved – Specimen copy requested

About ROWASOL:

ROWASOL, founded in 2004, is a specialist for high-end colour and additive dispersions, customer specific liquid colours and additive concentrates. ROWASOL's product portfolio is supplemented by a mixing and dosing system, adjusted to fast and clean changes of colours, for injection moulding, extrusion and special applications. These innovative technical solutions enable more efficient and thus more cost effective production processes. Our focus here is on the plastics processing industries.

Direct media contact and additional information:

Menyesch Public Relations GmbH

Thierry Krauser

Kattrepelsbrücke 1

20095 Hamburg/Germany

Tel.: +49 40 36986313

Fax: +49 40 36986310

E-Mail: rowa@m-pr.de

Enquiries:

ROWASOL GmbH

Udo Wilkens

Siemensstraße 1-3

D-25421 Pinneberg

Tel.: +49 4101 706335

E-Mail: u.wilkens@romira.de

www.rowasol.de