This has been overshadowed in recent times due to increasing demands for CO2 reduction, particularly in conventional finishing processes. ROMIRA however, has taken this development on board and is already positioning itself as an effective partner through its CRE.ACTIVE Design Mold In Color (MIC) solutions in metallic effect colors.

The wishes of customers can be described as follows: Alongside an elegant design and aesthetic appearance, scratches should be barely visible and restoration and polishing should be simple and easy. Then there are the additional, customary requirements and demands of the automotive industry in terms of quality and durability with regard to weathering, cleaning and use.

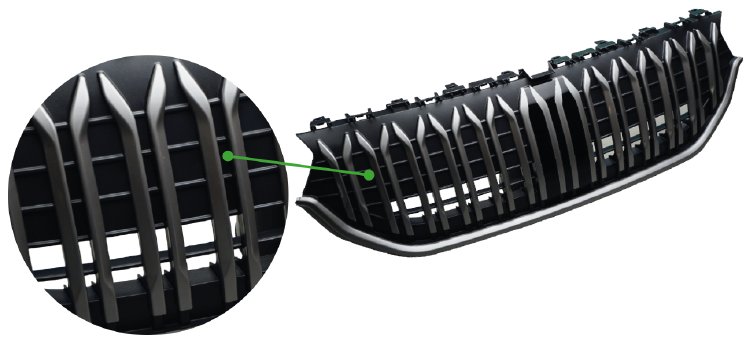

The advantages of using Mold In Color from ROMIRA are obvious: simplified production, no post-processing and the resulting reduction in CO2 emissions. Individual solutions for metal optics from ROMIRA are metallic effect colors. These have been continuously developed in recent years together with OEMs and partners from injection molding, toolmaking and pigment manufacturers. The knowledge gained from various tests has now made it possible to produce components that are barely recognizable as plastic and, for example, exhibit virtually invisible weld lines and flow lines.

Component design and mold construction are extremely important in this respect, as injection molding of effect pigments requires a different approach to conventional molds for single-colored plastics. An uninterrupted flow of the polymer melt must be guaranteed. In addition, rear ribs and clips should be oriented in the direction of flow as far as possible. Working closely with the Turkish-based automotive supplier Assan Hanil (Bursa-TR), among others, ROTEC® AC-MA was successfully used in metallic effect colors for the Turkish OEM.

With its latest Mold In Color solutions, ROMIRA once again demonstrates that it not only keeps abreast of the latest trends, but also helps to develop and shape trends, including in the automotive industry.