With Variotherm, the molding compound is injected at a much higher mold temperature that is beyond the softening point of the plastic. The high temperature that is used delays solidification in the boundary layer area of the component until after the mold has been completely filled during the holding pressure phase. Thanks to the higher mold temperature that is used during the injection process, the plastic material remains molten at the mold wall for longer so that phenomena such as the formation of bubbles, weld lines and the like are suppressed. In order to obtain adequate release stiffness after injection and to avoid a drastic increase in the cycle time, the mold insert is cooled after injection. This is achieved by a close contour and homogeneous temperature control of the mold.

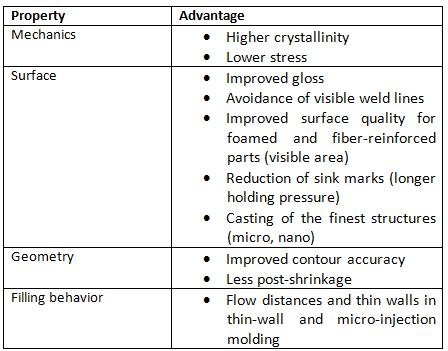

The Variotherm process allows the production of components with a high quality gloss surface finish and improved material structure that is free from common defects, such as weld lines, sink marks, and other surface inconsistencies. This form of processing also offers further advantages with respect to the mechanics and geometry of the moldings (see table).

This opens up unimaginable new design possibilities for product designers. For example, reinforced plastics with a completely smooth surface finish, without the need for additional painting can be produced using Variotherm, thereby enabling those parts to be used in visible cosmetic applications.

Apart from new design options, additional post-molding process steps for some parts can be reduced by using the Variotherm procedure thereby saving time and money. For glass fibre reinforced styrene-based copolymers and their blends, as well as Luranyl® products, Variotherm provides a good alternative to the more complex 2-component injection molding process. Advantages also arise in the case of microstructured geometries as well as macroscopic parts with a low wall thickness. Complex parts can be cast by preventing a premature solidification of the melt.