• Savings in time and personnel by means of radically simplified inspecting process.

• System of transponders, hardware and software

• RFID transponders as standard in RUD products

• Pioneer in RFID-based inspection of slinging and lashing means

More and more countries legally stipulate extensive inspecting of safety-related operating equipment and their legally compliant documentation. As the German premium provider of lifting and lashing means and pioneer in the RFID-based inspecting process design, RUD offers an easy and safe to use comprehensive solution, which radically simplifies these inspecting processes with RFID technology and thus permits significant savings in terms of personnel and costs. A special feature: The company is the world’s only manufacturer to integrate the required RFID transponders as standard in defined product groups. With the RUD BLUE-ID SYSTEM, the safety of the staff and lifting of loads increases and the legal certainty for a company will be established with a minimum of effort.

Savings in effort, personnel and cost

Example: In Germany, the inspection of safety-relevant operating equipment is anchored in the Operational Safety Ordinance (BetrSichV), and there are similar regulations in other countries. However, the conventional process from permanent identification of the products and testing to legally- compliant documentation of the test data requires a lot of time, personnel and costs. In particular, the identification and the documentation ties up immense resources every day. However, the process is essential. Especially as it is not only a matter of meeting legal requirements, but first and foremost of protecting people and last but not least of the loads to be lifted.Safety checks thus are in the company’s own interest.

Complete system from a single source

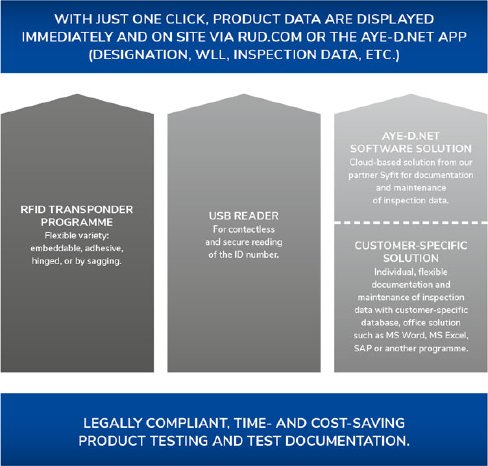

“With our RUD BLUE-ID SYSTEM you can significantly reduce inspection costs and times, while simultaneously increase process safety thanks to error prevention”, explains Hermann Kolb, division manager of the Sling & Lashing Business Unit at RUD. The system consists of three components: RFID transponders, the hardware to read the factory-provided unique identification number and a special software solution to document and manage the test data. According to Kolb, the Aalen company was a pioneer in the RFID-supported inspecting of sling and lashing means and profit until this very day from this wealth of experience: “At the moment they are the world’s only manufacturer in this area, who does equip products as standard with integrated RFID transponders.” For other products the transponders can be retrofitted.

The right transponder for any application

RUD offers a range of additional transponders that are extremely resistant even under tough conditions according to RUD. Depending on the variant and type of the equipment they can be pressed in, glued on, suspended or integrated as additional chain link. A unique identification number is stored in every RFID transponder. During the test, any RUD component equipped with an RFID transponder can be identified contactless and error-free with just one click. The RUD USB-ID READER, which is compatible with all conventional high-frequency transponders and chips according to ISO 15693 can be used for this reading. It can be interconnected via Bluetooth adapter / USB cable with the PC, tablet, laptop or smart phone and sends the identification number to a documentation and management software.Also off-line testing with subsequent data synchronisation is possible. Additional benefit: Important product data can - regardless of tests - be accessed directly at the equipment on site via app or RUD website.

Very easy test documentation and management

The user can choose the software for documentation and management. He can either use existing databases and standard programmes such as Office applications or SAP. The other option is to use the specially developed, cloud-based software AYE-D.NET that RUD offers together with the partner company Syfit as SaaS solution (software as a service). Thanks to the SaaS model, installation, software maintenance and hosting are not required. AYE-D.NET combines testing software, management software and documentation software. This permits easy digital maintenance, analysis and management of product data, test reports and documents. Furthermore, the software reminds you of legally required tests, creates automatic rest reports and archives them. “The entire testing of operating equipment therefore requires very little time”, stresses unit manager Hermann Kolb. In addition, the system can be easily expanded to other operating equipment and work equipment subject to testing.