With the SCANalign vision system, users can realize high-precision laser processing in low-precision environments: the system automatically recognizes and locates fiducial markers or other features on workpieces, so that the laser beam can be very precisely positioned with respect to these fiducials. The result of the laser processing is thus more precise than any part or mechanical fixture in the machine itself. In addition, the vision system allows calibrating the working field and checking the result of the laser process. Users can follow the processing online, or on a PC or remote terminal. In simple terms, SCANalign provides self-aligned laser processing.

The SCANalign vision system takes pictures through the laser scan head and is easy to use and set up. By observing the workpiece through the scan head, the system effectively corresponds to a camera with over 100 million pixels. This yields high precision for measuring features across the complete working field. Precision is higher and the working distance larger than in typical vision systems.

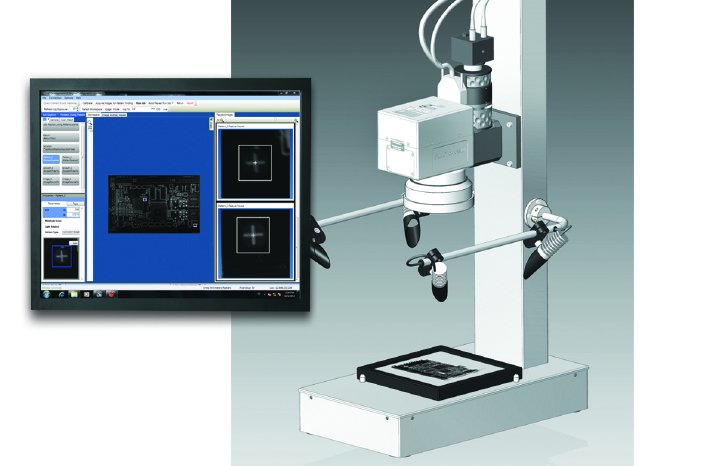

The SCANalign system consists of a software package with an intuitive graphical user interface, a camera, a camera adapter, an illumination system and a high-precision calibration plate. The user does not need to write or check computer code. All components are reliable and industry proven. A stand-alone and an OEM bundle will be available. The vision system interfaces seamlessly with SCANLAB's laserDESK software. Training, installation and support, including in the domain of illumination, are provided. SCANalign is an integrated solution that saves the user man-years of engineering effort.

SCANalign is perfectly suited for solar cell processing, processing of medical parts, micromachining, high-volume engraving of small parts and many other applications. The system will also be available for the intelliWELD scan heads used for high-power remote welding in the automotive and other industries.