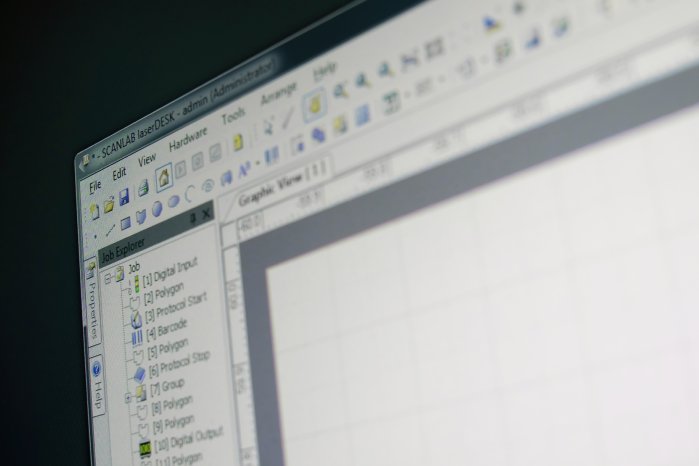

More and more industrial processing steps rely on lasers. Efficient operation of laser systems can be hugely simplified via intuitive software that lets you create marking templates and set up and manage laser material processing tasks. Developed by SCANLAB and with over five years of market success, laserDESK is precisely tuned to the company's RTC5 control board and high-performance scan systems. Maximum flexibility is achieved, because even during execution of complex jobs, you can select diverse processing sequences immediately. As well as improved ease of use, Version 1.2 offers fundamentally new functionalities.

Additional Features

New remote commands now enable the program's integration into system control as well as ‘slave’ or as ‘master’, thereby allowing fully automated complex marking operations and dependencies. The new ‘Parameter Assistant’ greatly simplifies determining and setting key process parameters – e.g. laser powers, laser frequencies and scanner delays – for a specific job. Optimal parameter settings can be issued, read or selected via a tiled overview with a pre-defined test structure or customizable elements.

Additionally integration with the SCANalign image processing solution has been further enhanced. Markings can be exactly positioned on every workpiece thanks to automatic image data transfer from the calibration system. Distortion-corrected images embedded directly in laserDESK's user interface also allow visual monitoring of process results. laserDESK's new version is usable offline, too – for when you only need to prepare and edit processing tasks.

And of course the program retains all its features for creating individual processing templates via a clearly-structured graphical user interface. All marking objects can be assigned individual process parameters. Library functions ease reuse of objects and parameter sets – that saves work time and avoids fatiguing repetition.