The two companies have already been collaborating on the design and development of scan solutions for microprocessing since 2019. This new project also means that SCANLAB will take on joint responsibility for the distribution of highly integrated laser scan systems, allowing the organization to provide its own customer base with additional, integrated solutions from February 2022 onward. The market for USP applications (ultrashort pulse lasers) is continuing to grow; in general, the most significant challenges involve achieving desired increases in throughput. Parallelization of laser processes using multi-beam systems can help to overcome this precise challenge.

Integrated scan systems for beam shaping

The Microscan Extension (MSE) could also be described as a ‘1 µm laser blade’. This scan lens easily transforms a scan head into a micro-spot scan system. The combination of a galvanometer scanner and MSE enables highly precise component processing: The focus diameter is less than 4 μm and even less than 1.5 µm in the UV wavelength range.

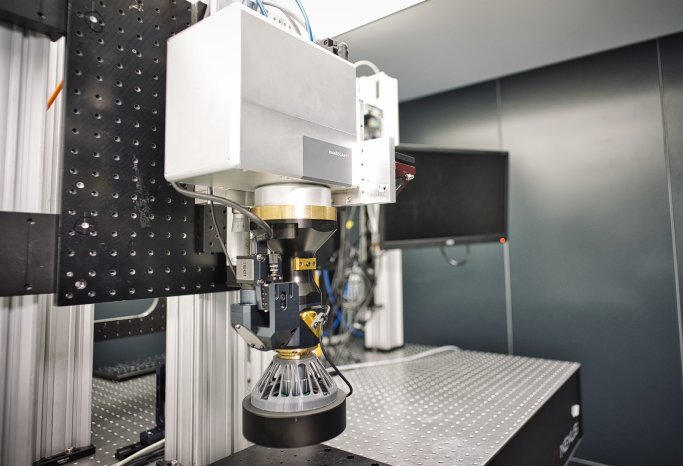

The MultiBeamScanner (MBS) is a scan solution that enables laser cutting, drilling and removal processes to be performed simultaneously. The use of diffractive optical elements (DOE) divides the incident laser beam into a configuration made up of multiple partial beams, enabling multiple laser spots to be worked on at the same time in a single image field. This means that multiple components can be processed at the same time or that structures can be produced more quickly. Combining this technology with the XL SCAN solution further improves the precision and speed of parallel laser processing.

The most complex system is the FlexibleBeamShaper (FBS). The FBS is a beam shaping system that can be integrated into a machine and can generate user-defined beam distributions as required. Thanks to the optical phase modulator, which can be controlled electronically, the FBS is, so to speak, a ‘photonic toolbox’ containing a range of predefined beam shapes. The system, featuring an integrated galvo-scan head, opens up new possibilities for process developers when it comes to flexible, efficient microprocessing.

The Beam Alignment Module (BAM) is used to actively stabilize the beam position. Alignment errors, thermal effects caused by laser sources, variations in the ambient temperature, and all their resulting effects on the beam position can be measured and corrected. As a result, the BAM ensures that process results remain consistent, even when the environmental conditions change.

The joint development work continues

The collaboration between USP expert Pulsar Photonics and SCANLAB goes above and beyond a typical joint distribution project for the specified products. Over the course of their ‘Photonics Drill Engine’ (PDE) development project, the two businesses will jointly develop an extremely dynamic, versatile multi-beam tool for laser material processing. This technology is particularly suitable for use in the electronics industry, for instance for laser drilling circuit boards in order to increase drilling rates for high-density applications. The companies' journey together has only just begun.