Selector hubs in transmissions: With its new selector hub made of sheet metal for example, Schaeffler can now facilitate reductions in weight of up to 25 percent compared with a conventional solid sintered metal version. The new two-part design comprising geometrically-compatible sheet metal half shells can even transmit higher torque than sintered components after optimization of the design process.

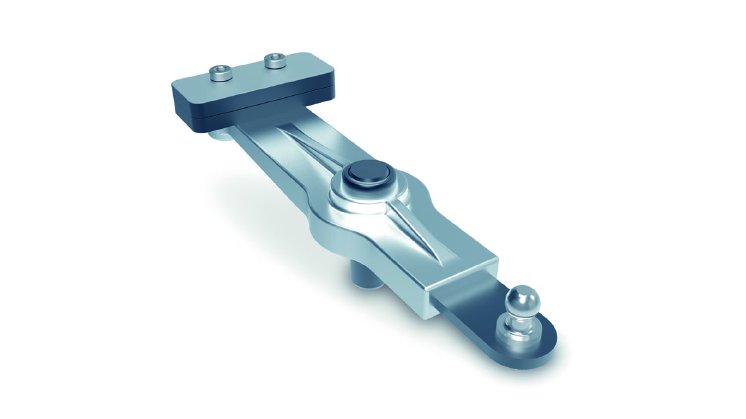

Hybrid design gearshift forks: The intelligent use of mixed constructions is key to opening up further potential for improving efficiency in manual transmissions. For example, Schaeffler's new hybrid gearshift forks, which can replace more traditional and conventional steel gearshift forks, have bodies made of aluminum. The striker jaw is a high-precision sheet metal blanked component. During the assembly pro-cess, the striker jaw is precisely aligned in the screw mounting plane and joined to the gearshift fork, allowing single component tolerances to be compensated. Costly recasting as required with conventional aluminum gearshift forks is not necessary during the manufacturing process of Schaeffler's hybrid gearshift forks. In addition, complex reworking of the assembly is not necessary. This mixed construction not only reduces the weight of Schaeffler hybrid gearshift forks compared with that of conventional solutions, but also makes them more compact. This reduces the design space required.

The simple assembly process means the hybrid design can easily be manufactured all over the world. These hybrid gearshift forks are already in volume production with one customer and other volume production applications are set to follow.

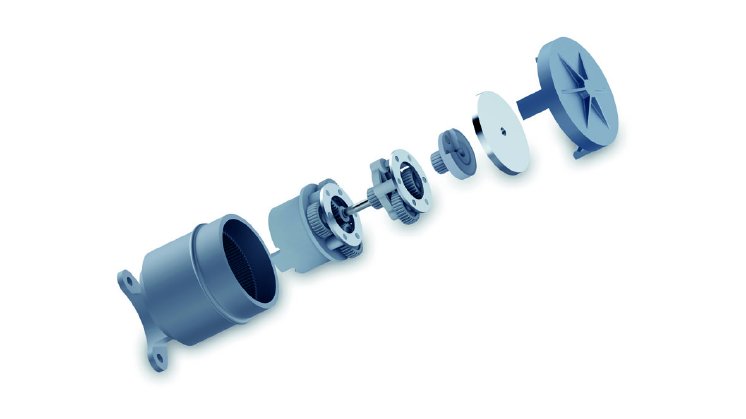

Shift mass: Reductions in weight and design space can also be made with shift masses, while simultaneously allowing increases in driving comfort. Conventional shift masses comprise a steel component with a high mass. They generate mass inertia thereby balancing out force peaks and vibrations that occur during gearshift operations.

Schaeffler offers two solutions here with optimized mass. The mass of Schaeffler's i² shift mass module has been reduced by up to 70 percent compared with that of conventional components. However, the i² shift mass module's lower inertia level is increased using a gearbox. A two-stage planetary gearbox that enables very high ratios forms the core of this gearshift module. A slipping clutch reduces the load on the plastic gear teeth during overloading thereby helping to ensure a long operating life. Schaeffler's lightweight shift mass involves using another approach by improving the distribution of weight of conventional shift masses. Fitting the actual mass on the outer end of the lightweight carrier ensures optimum utilization of the the lever action provided. The lightweight carrier is made of aluminum or plastic in conjunction with a steel gearshift lever for transmitting the gearshift force.

"Schaeffler's new lightweight concepts enable reductions in weight of up to 1.2 kg to be made in transmissions", explains Pascal Kohtes, product developer at Schaeffler. "Lightweight constructions often not only have an effect on the components themselves, but also initiate significant positive secondary effects for the vehicle as a whole. These range from advantages in driving dynamics and reducing weight to cutting fuel consumption and CO2 emissions. Lightweight constructions are therefore a specialist area with a strategic focus that will dominate mobility in the future."