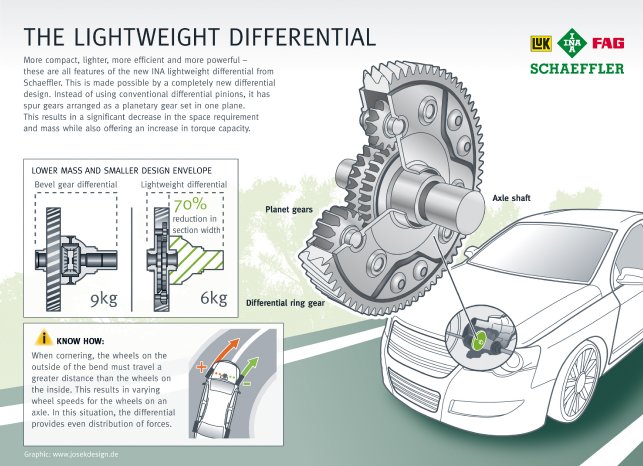

The architecture of this space-saving component is completely different from traditional differential designs. Instead of using conventional differential pinions, the lightweight differential has spur gears arranged as a planetary gear set in one plane, as used in automatic transmissions.

This means that the required space and weight are significantly reduced and the potential torque capacity is noticeably increased. "The lightweight or spur gear differential has enormous advantages", explains Dr. Tomas Smetana, Head of Advance Development at the Transmission Business Unit, Schaeffler Group Automotive. "We save up to 30 percent weight compared with a classic bevel gear differential while creating up to 70 percent more axial space due to the streamlined design. In specific terms this means a reduction in mass of up to three kilograms per differential and 90 millimeters of additional space in the transmission!" The lightweight differential is thus an appropriate response to the challenge of increasing engine torques and the space gained in the transmission creates more room for larger double clutches or transfer boxes, as well as electronic components for modern hybrid solutions.

"The narrow lightweight differential design also allows the use of new bearing concepts with optimized friction and makes a measurable contribution to reducing fuel consumption and CO2 emissions", says Norbert Indlekofer, member of the Executive Management Board of Schaeffler Group Automotive and responsible for the Transmission and Chassis systems Business Division.