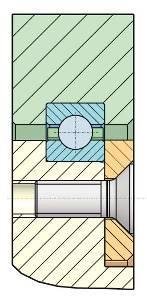

CSX formed thin-section bearings are four-point contact bearings with a contact angle of 45 degrees. Open on both sides, they are available with five cross-sections and as cross roller bearings. The four-point contact can accommodate combined loads. The new thin-section bearings can be used at temperatures of between -40 and +120 degrees Celsius. Their bearing rings and cages are split so that varying rates of expansion of the different materials can be compensated. In addition, users can choose from a wide selection of materials for the adjacent structure (e.g. aluminum). Further advantages of the new formed thin-section bearings include simple, quick and economical mounting and dismounting, since no special tools are required.

The plastic cages are made from Pa12, or optionally from PEEK. Comparable to a traffic light, the cage colors indicate the bearing clearance: A red cage stands for preload, a green cage means normal clearance and a yellow cage indicates increased bearing clearance.

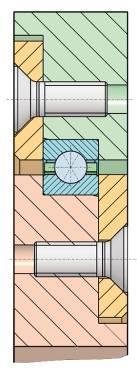

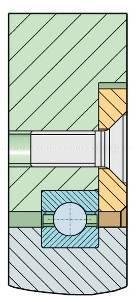

Users can choose between two mounting options: The bearings can be anchored either on one or on both sides. If the formed thin-section bearing is to be anchored on one side, this requires a shaft or housing shoulder. When the bearing has been slid onto the shoulder, the outer or inner ring is secured with a washer. For the second variant - anchoring on both sides - both the housing and the shaft must feature a shoulder. The bearing is then slid onto the shoulders and the inner and outer rings are each secured with a washer.

In addition to medical technology, the new product family is also used in a wide range of other applications and industrial sectors. Examples include applications in electronics manufacturing and automation technology, industrial robots, rotary indexing tables, tool changers, power tools, machine tools and the food industry as well as in agitators, packaging machines, augers, winches etc.