Electric mobility is gaining momentum: Vehicles with alternative drive systems are regarded as a central component in the fight against noise pollution and steadily rising emissions. The heart of these vehicles is the built-in high-voltage battery. Thermal influences have enormous effects on its service life, capacity and especially its operational safety. For the normal operation of an electric vehicle, operating temperatures of approx. 20 to 40°C are ideal. Excessive thermal loads can cause internal short circuits and consequently severe to irreparable damage to the HV battery and vehicle.

To prevent this from happening, large quantities of thermally conductive paste are used in addition to the built-in cooling system. For each vehicle, about 5 to 10 liters of these highly viscous and highly abrasive media are dispensed in between the battery modules and the enclosing housing. They ensure reliable heat dissipation and thus contribute to the prevention of potential defects caused by overheating. Due to their high viscosity and the high proportion of abrasive fillers, however, the application of thermally conductive materials places high demands on the used dispensing technology. Furthermore, this process step often proves to be a bottleneck in fully automated production processes, since these media often only allow relatively low dispensing speeds.

Material application with up to 80 ml/s

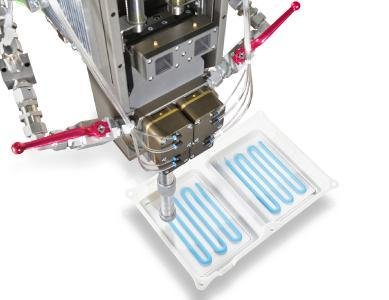

Scheugenpflug has developed a new dispensing solution specifically for the encapsulation of HV batteries. The system, consisting of the high-performance dispenser Dos HP and the PailFeed200 Abrasive material feeding unit, offers dispensing speeds of up to 80 ml/s even when using highly abrasive thermally conductive media. The simultaneous coupling of two feeding systems with the dispenser allows continuous system operation without downtimes. The new system solution has been designed for easy operation and maximum robustness. Users thus benefit from simple and fast maintenance, long service life and significantly reduced maintenance costs.

The high-performance dispenser Dos HP allows the fast and precise application of heat-conducting media with a viscosity of up to 1,000,000 mPa∙s and a maximum volume per shot of 310 ml. The follower plate pump PailFeed200 Abrasive for 200 l barrels ensures the reliable transfer of potting material to the dispenser. The integrated double piston pump with a delivery volume of 480 cm3/stroke allows for a continuous material feed. Thanks to the high delivery pressure of 65 bar, a high output is guaranteed – even when using highly viscous and highly filled thermally conductive pastes.

Learn more about thermal management for HV batteries and our system solution for battery encapsulation in our new video:

www.scheugenpflug.de/en/hv-battery-system