When adopting a new technology, all markets seek a low-cost solution. In the case of 2C dispensing cells the matter mostly revolves around how to automate the inefficient process of manual dispensing, which often lacks sufficient quality. Another aim is to achieve higher flexibility. For example, it is impossible to apply exact lines manually. But exact lines are required for a growing number of sealing applications when producing electronic components.

A closer look reveals that Asian, European and American electronics manufacturers have very different requirements in mind when they inquire for low-cost entry-level models. While in the past different models were built for different markets, this is no longer the case with the new DesktopCell. The dispensing cell can be used efficiently and sustainably for the widest variety of tasks. Therefore, its semi-automatic design, which can be easily integrated in lean production environments anywhere, is of great interest to electronics manufacturers across the globe.

Many manufacturers, especially in the industrialised Asian countries, still mix and process casting resins manually. The resulting dispensing quality hardly ever meets today's requirements any longer. Manual dispensing is highly inefficient and does not meet the pressing demands for shorter time-to-market. The new system opens new perspectives to electronics manufacturers in the lighting, automotive and consumer electronics sectors, many of which are based in Asia.

In Europe and America, on the other hand, different concerns prevail. A very recent topic in these countries is e.g. to achieve high process reliability when applying gap fillers or thermally conductive pastes. Processing of these media requires a combination of precise metering, accurate positioning and high repeat accuracy. The DesktopCell is custom-built to meet all these requirements, while at the same time offering the full range of processing technology and process reliability.

This entry-level system is suitable for any small to medium-size production set-up where high accuracy and process reliability is needed. It integrates easily into lean production environments. A tried and tested set-up e.g., would be to manually bring and fetch the substrates, while dispensing is carried out automatically.

Low Costs But High Quality and Performance

It is easy to control the costs of a dispensing cell system by focussing on its scope of functionalities and on how to standardise its features. Many systems offer functionalities which are hardly ever needed but expensive to build. Against this background, Scheugenpflug thoroughly analysed market requirements and then focused on the essence of the dispensing process. The result was the DesktopCell which includes all the functionalities needed for typical continuous production applications and provides maximum process reliability. A dispensing cell's performance is measured by its accuracy, process reliability and high flexibility regarding the work pieces that it can process. There is hardly an electronics manufacturer today, who knows what will be needed tomorrow. Therefore, it is important to be able to produce what the market needs, without much additional effort. This is where the DesktopCell comes in, a perfect starter model to introduce lean production equipment, as offered by Scheugenpflug. With our machines it is easy for electronics manufacturers to adapt their production set-up to new requirements.

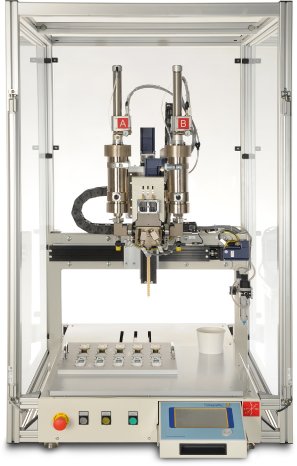

The ratio of footprint to movement range of the new dispensing system has been improved considerably (X and Y axis: 500 mm, Z axis: 300 mm) - although the cell's dimensions of 880 x 1130 x 1400 mm (width x height x depth) were clearly reduced. The machine can process work pieces of 600 x 600 mm and 20 kg max. As before, the XYZ linear axles are built with precision spindles and high-performance drives with closed-loop control.

A major cost-minimising factor is the use of the Scheugenpflug SCP200+ control unit, which is used as a standard module in all material preparation units. This saves licence costs and offers all the familiar controls. All work steps are easy to learn and operate, which largely minimises training efforts and costs.

Another significant cost-saver is the fact that the DesktopCell is manufactured using lean production methods, the production standard implemented at Scheugenpflug. This production method reduces manufacturing costs and at the same time allows faster cycle times and quicker delivery.

Ready Today for Tomorrow's Requirements

Today, the production of electronic parts and components needs to adapt quickly to changing requirements. A very recent example is the increasing use of liquids instead of pads. These highly abrasive and highly viscous thermally conductive pastes are very demanding for the mechanical parts of a metering and dispensing system. Most compact-sized cells on the market are only able to support and move only time or pressure dispensers. But these are not suitable for processing highly abrasive dispensing materials, neither in terms of functionality and service life, nor in precision. The DesktopCell, on the other hand, uses the proven Dos P016 piston dispenser. This volumetric metering unit is highly performant and shows an exceptionally long service life, especially when handling highly viscous and abrasive media. The dispensing system is purpose-designed to work with this type of metering unit, which is ideal to meet the changed requirements in the production of electronic assemblies. This clearly sets the DesktopCell apart on the market and gives users greater freedom in processing a wide range of dispensing materials. For example, if non-abrasive materials need to be used in a production run, this is easily possible: The system also handles simple metering and dispensing tasks (dots or lines and filling) and is designed for processing a wide range of different dispensing materials, including highly filled media.

Find Out Your Future Options Now

The idea of the DesktopCell shows that it is possible to develop systems which meet today's needs of electronics manufacturers for entry-level equipment to produce parts and assemblies. One thing is clear: The starter model is no replacement for other dispensing systems. It is the first step on the road to automated production. With the DesktopCell, the production supervisor has a system which establishes a well-working semi-automated dispensing process and offers the precision, process reliability and dispensing quality of full-scale systems. This is made possible by the use of a tried and tested piston dispenser, which is also included in all the large Scheugenpflug systems. The procurement head will cheer the low purchase costs and the upper management will appreciate the appropriateness of the investment, the new range of processing and material options and the possibilities this new machine offers to meet future demands. Because what matters depends on who is asking.