Given the diversity of laminar flow applications and the comparatively low flow velocities with narrow tolerances, great demands are made on laminar flow monitoring. Reliable flow measurement based on high precision measurement technology must be ensured in the long run. Furthermore, the design and the materials used for the flow sensors have to meet the specific conditions of a cleanroom environment.

SCHMIDT® flow sensors SS 20.415 measure flows from 0.05 m/s (standard velocity wN of air, based on standard conditions 20°C and 1013.25 hPa). The ISO 14644 standard defines that the measuring range starts at 0.1 m/s. In addition to accuracy and long-term stability, the short response times of the SS 20.415 flow sensors make it possible to achieve a high standard of quality in laminar flow monitoring. They can be configured in a range from 0.01 to 10 seconds, which ensures, for example, good control behavior of the ventilators.

GMP-compliant design means that all surfaces of the SS 20.415 are smooth, without undercuts or hidden cavities. The sensor tube and the mounting parts on the cleanroom side consist of high-quality stainless steel 1.4571. Only the very small sensor head and the sensor element contained in it are made of different materials, having proven their resistance to alcohol and hydrogen peroxide disinfection in extensive laboratory tests.

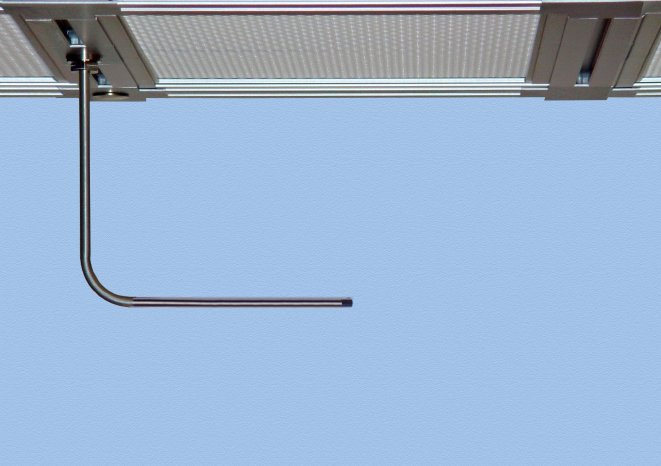

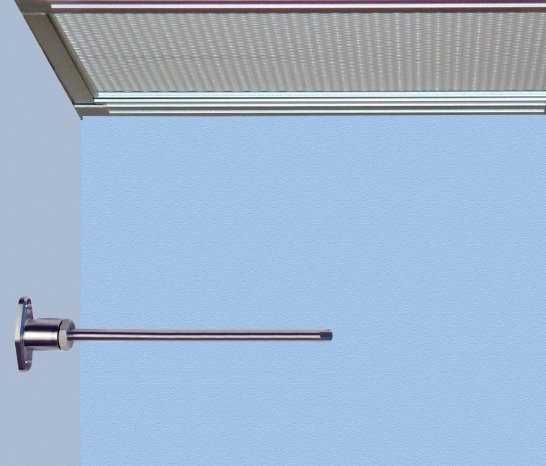

The extremely compact and robust design is a distinctive feature of the flow sensors from SCHMIDT Technology. Franz Brockhaus, design engineer at FRANZ ZIEL (FZ) Reinraumtechnik confirms that the particularly slender sensor tube, having a diameter of only nine millimeters, does not create any turbulence in the low-turbulence displacement flow. The company located in Billerbeck in the Münsterland region uses SCHMIDT® flow sensors in various designs and mounting options and particularly appreciates the benefits of universal use thanks to the identical design of the sensors.

Since 1982, FRANZ ZIEL (FZ) Reinraumtechnik has been manufacturing devices and systems for laminar flow cleanroom applications. Their product range includes LAF systems (Laminar Air Flow), RABS systems (Restricted Access Barrier Systems) and isolators. All systems are designed and customized to meet the customer's specific requirements.