With the product name "Schüco LivIng", Schüco is appealing to both end customers and fabricators. For the client, "LivIng" conveys emotive values such as comfort, security, energy efficiency and design while, for fabricators and architects, development expertise and fabrication benefits come to the fore.

A world first in gasket technology

Together with its development partner Semperit, the company has created the first weldable EPDM gasket for Schüco LivIng, which is exclusively available to Schüco partner companies. The gasket combines the advantage of long-term weathertightness which is typical of EPDM gaskets with the weldability of, for example, TPE gaskets. This allows a continuous gasket frame to be created without hard weld seams - with increased watertightness in the corner areas and a closed appearance of the corners. The top-quality material retains its high sealing effect throughout its useful life. It is UV-resistant, stable in cold temperatures and suitable for use in all types of buildings and climate zones, offering permanent elasticity in temperatures ranging from -40 to +120 degrees Celsius. Schüco is currently the only system provider to be able to offer its customers such a high-quality EPDM gasket rolled as standard.

Flexibility and efficiency during fabrication and installation

Schüco LivIng saves fabricators time and money when planning, ordering, fabricating and installing. The uniform gasket concept, vent profile and fittings components are equally suitable for the centre gasket and rebate gasket system. Corresponding rebate base geometry in the vent and outer frame allows quick fabrication thanks to identical drilling and machining settings. The same connectors for mullions and sash bars as well as identical steel reinforcements in the outer frame, vent frame and double-vent profiles are further examples of design details which offer the fabricator increased process reliability with reduced storage complexity.

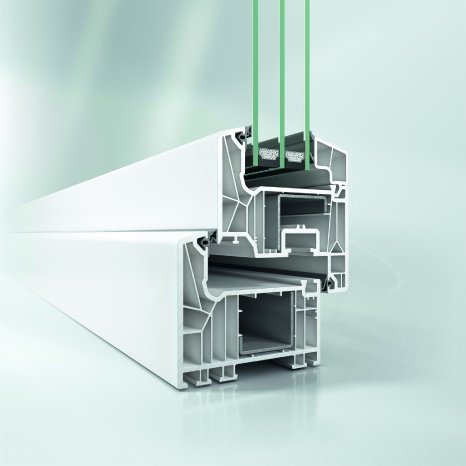

Energy balance and security

As a 7-chamber profile construction with a basic depth of 82 mm, Schüco LivIng achieves outstanding Uf values as low as 1.0 W/(m2K) for the rebate gasket version and 0.96 W/(m2K) for the centre gasket system. This means that even passive houses can be constructed without resource-intensive additional measures - triple glazing and functional glazing up to a thickness of 52 mm can be used. Schüco also offers tailored fittings options for security technology: Schüco LivIng windows and doors can be constructed to meet resistance classes up to RC 2.

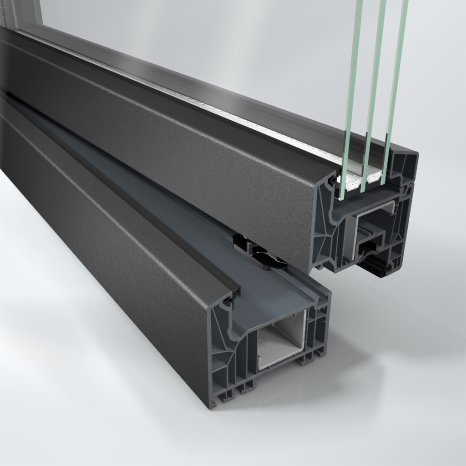

Flexibility and design

Schüco LivIng is available immediately. With 7 outer frames, 8 vent frames, 3 double-vent profiles, 5 sash bar and T-profiles, as well as 15 glazing beads, a complete system is on offer. It is complemented by a comprehensive range of attachment and supplementary profiles. There is also an unlimited choice of colours. The exclusive Schüco AutomotiveFinish surface finish technology endows Schüco LivIng windows and doors with brilliant metallic designs, which are otherwise only to be found in the automotive industry. In addition to the 11 familiar colours, three new shades are now also available: Light Silver, Deep Bronze and Metallic Black. The Schüco range of foils with a selection of over 160 single colours and woodgrain finishes as well as aluminium cover caps in the Schüco TopAlu series (availability expected from the end of the third quarter of 2016), which cover all RAL and anodised colour shades, offer a wide variety of design options. In keeping with the trend for different shades of grey in the construction industry, Schüco LivIng is also available with a grey base component. This ensures an harmonious appearance, particularly when the window is open.