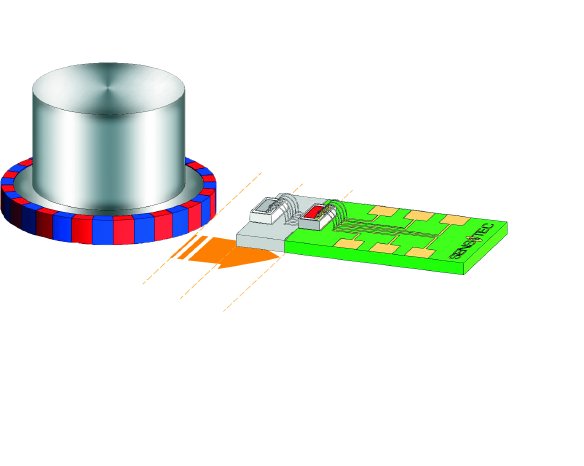

The higher sensitivity results from the fact that the sensor geometry and layer structure were designed in such a way that the field strengths from only approx. 3 mT are sufficient to bring the sensor into saturation mode, where it achieves its optimal performance. High resolutions and measuring accuracies can then be realized. For the design and layout of an encoder system this means that the sensor can be placed further away from the measuring scale (e.g. a pole ring). This is ideal for heavy-duty encoders, e.g. where components with greater wall thicknesses are required or larger air gaps between sensor and measurement scale are necessary. Due to the magnetic, non-contact measuring principle, the sensor can be completely encapsulated providing an extremely robust design.

Advantages of the AA746 at a glance:

- Larger air gaps of several mm possible

- Sensor designed for shaft end, shaft circumference and linear measurement

- Very high accuracy and minimum hysteresis

- Various package forms available for SMD assembly