STW provides customer-specific adaptation developments based on the mBMS construction kit for the large potential diversity of application possibilities. Here the assembly geometries are adapted and special functions and alternative interfaces are implemented. Thanks to the secure computer architecture with two controllers (Infineon XC, Infineon TriCore), an application processor is provided which executes customer software without compromising the security functions. In this way, mBMS customers can for example incorporate their own algorithms for condition evaluations.

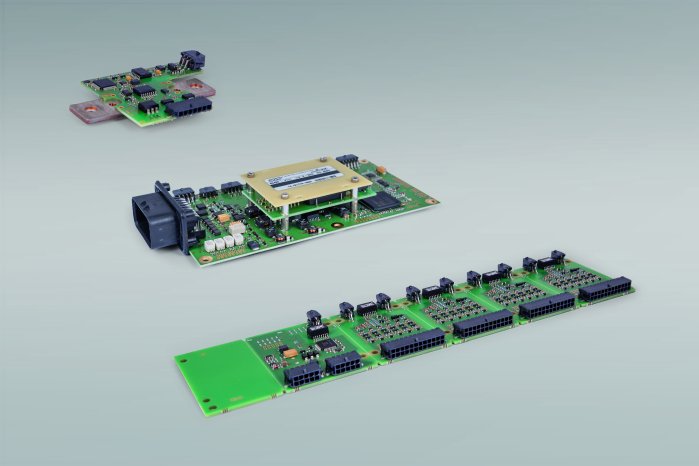

The developers have placed particular emphasis on convenience. With the “mBMS Toolchain” included in delivery, the battery integrator on the mBMS can easily configure its battery memory and conduct diagnostics on the running system. Optionally, a special program code can be added which keeps the timeframe for successful commissioning exceptionally short. The mBMS is available as an “off-the-shelf” solution in the form of three key assemblies: The central BMS (“Battery Main Supervisor”), a multitude of cell monitoring assemblies (“Cell Sensor Circuit”) and the current sensor (“Power Measurement Board”). All assemblies are suitable for battery voltages up to 800 volts, and two sensor types are available for 300 and 600 ampere for current measurement.

All required sensor and actuator functions are implemented: Monitoring of all cell voltages with the precision measurement module LTC6804 by Linear-Technology, shunt-based current measurement, all-pole disconnection of the battery with installed contactor diagnosis, assessment of crash and interlock signals, adaptive pre-charging of the intermediate circuit, performance prediction in charging and discharging direction, State-Of-Charge (SOC) determination with Coulomb Counting and automatic capacity determination. All conventional classes of lithium-ion cells are supported. The communication with the superordinate infrastructure is undertaken via CAN interfaces. In this way, it is also possible to conduct remote maintenance and diagnosis with STW ESX Controllers and the CONNEX data management solutions. In particular for mass storage devices, it is of advantage to be able to switch batteries in parallel. The mBMS supports this option from the start – up to eight high-voltage storage devices of the same type can be switched in parallel. The management of the batteries and the calculation of the power data are executed autonomously by the mBMS.

Visitors can experience the new mBMS in Hall 13, Booth C16 – the joint booth of Bayern Innovativ.