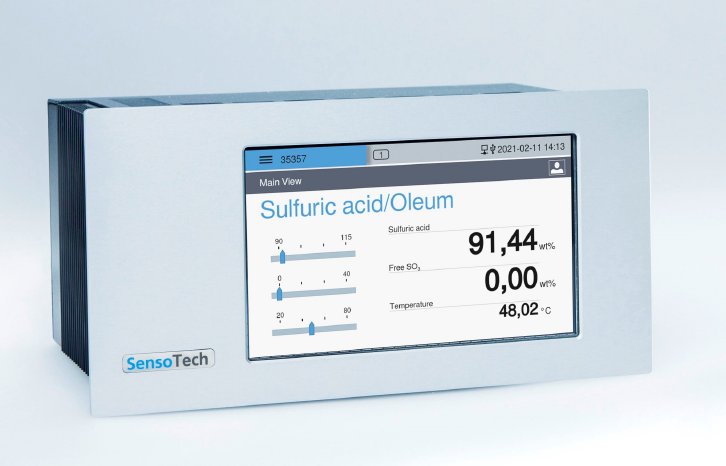

LiquiSonic® - The smart process monitoring system

By using a feature specially developed for this requirement, switching between the areas is fully automated with the LiquiSonic® measuring system from SensoTech GmbH. The concentrations are determined with a specially developed calculation model, displayed and, if desired, passed on to a process control system. Compared to the separate inline measurement of both components, the simultaneous inline measurement has clear advantages. While the respective calculation model must be selected for individual measurements, this work step is completely omitted. This has the advantage that the concentrations, especially around the switchover point, can be determined exactly at any time and in a matter of seconds. Manual identification and switching are no longer necessary.

If necessary, the maintenance-free measuring system LiquiSonic® offers the possibility of adjusting the calculation model to emerging additional components, gas bubbles and other disturbing factors. The device can thus be used very flexibly and adapted to changing process conditions.

The simultaneous monitoring of sulfuric acid and oleum with LiquiSonic® thus revolutionizes the workflow in production plants. By saving time-consuming and inaccurate sampling with the help of simultaneous inline measurement, an increase in efficiency is possible immediately after installation of the measuring system.