In contrast, the group member can look back on a whole series of innovations and improvements in transformer design and technical implementation.

In the case of cast resin transformers, for example, this includes the SGB Safe System for the protection of people and the environment, the SGB Jet System cooling system or a layer winding used exclusively by SGB. In addition, over the decades, SGB transformers have been continuously optimised in those areas to which our customers attach particular importance, namely

- Climate resistance

- Environmental protection

- Lifetime

- Service-friendliness

- Transformer dimensions

- Economy

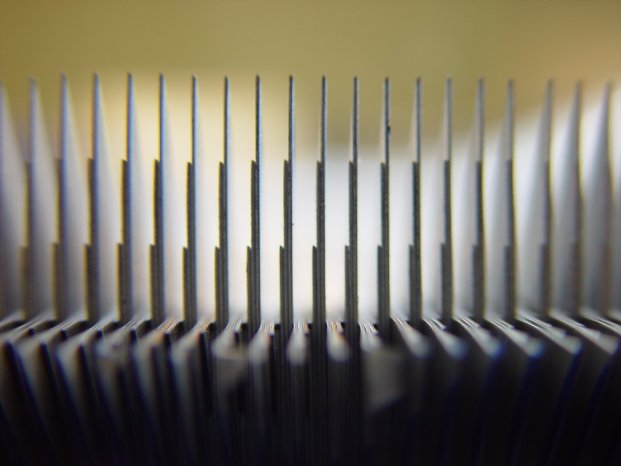

By using this top grade, we can keep no-load losses by a further 10% lower than all other conventional electrical steel available on the world market without negatively affecting productivity.

For the customers of SGB Regensburg this results in two significant advantages:

- For the same size, a transformer produced with this material has significantly lower no-load loss values and thus achieves increased efficiency.

- Conversely, for a given loss target, transformers can be produced with a smaller size and less weight, since comparatively less core material is required to achieve the target values.

SGB Regensburg is currently producing a transformer with a rated output of 1,750 KVA and no-load losses of only 1,500 W. For comparison: At this output, the ECO design guideline stipulates a maximum of 2,350 W according to stage I and a maximum of 2,115 W according to stage II. Even the Eco 2 losses, which will not apply until July 2021, are thus undercut by around 30%.