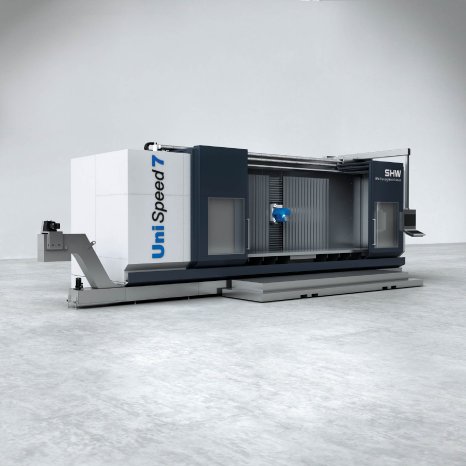

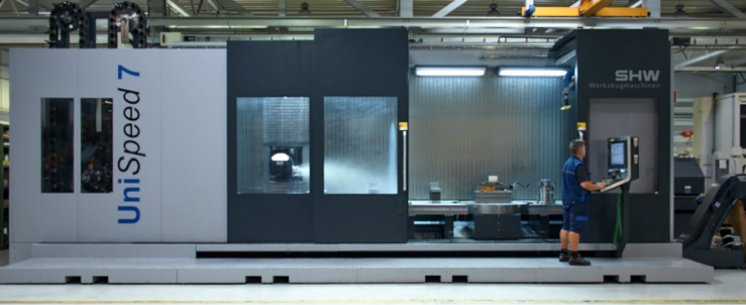

"With the basic version of the new UniSpeed 7 we offer an extremely high-performance tool for machining large parts at an attractive price", assures Christian Hühn, Managing Director of SHW Werkzeugmaschinen. At the AMB, besides numerous extremely interesting innovations, the company is displaying a complete UniSpeed 7 machining centre for large parts. Workpieces up to six metres long can be quickly and precisely machined at a single setting. The working zone is up to 6000 mm on the X-axis, up to 1600 mm on the Y-axis, and up to 1300 mm on the Z-axis. But still the machine needs no special foundations.

UniSpeed 7 manages without foundations For shuttle machining the working zone can be equipped with a partition wall so that setting-up on one worktable can proceed in parallel with machining on the other. This increases the machine's effective running time. "On the machine displayed we have also integrated two rotary tables in the working zone", stresses Martin Rathgeb, Technical Director of SHW Werkzeugmaschinen GmbH. That increases the range of applications, and yet the machine still has relatively compact dimensions. The machine is equipped with two magazines for up to ten tools. The unique SHW Orthogonal Milling Head fetches the tools automatically and changes them in a flash.

In addition the resourceful designers at SHW Werkzeugmaschinen have optimised swarf disposal and redesigned the machine's bed for even quieter running and more stability. As with every SHW machine, users can configure their UniSpeed 7 especially for their own machining spectrum. Numerous functions, tool changers with up to 120 tools, and an exceptionally practical Service App for "Industry 4.0" preparation can be configured. A further highlight is the latest Heidenhain control system iTNC 640.

Specialists for out-of-round / eccentric turning The machine is part of the UniSpeed family. With the two other machines in this model range, UniSpeed 5T and 6T for simultaneous turning, SHW Werkzeugmaschinen has matured into a top specialist for out-of-round / eccentric turning. Worldwide the manufacturers of large butterfly valves and fittings for the petrochemicals industry and pipelines swear by the high precision, exceptionally energy efficient and economical machines from Aalen. Visitors to the AMB can convince themselves of the competence of this company whose roots go back 650 years.