The importance of surfaces in a wide range of products is obvious. Coatings protect surfaces from the environment and improve the look, feel and performance of products ranging from garden furniture to cars and airplanes. When developing modern coatings, paints or inks, the formulations are complex and the interactions between individual components are many. At the same time, the demands for safety and environmental compatibility are high. In practice, many different formulations are often conceived, created, tested and then discarded or modified. This process is not ideal, but is usually unavoidable due to the complexity involved. Negative side effects are wasted material and a considerable amount of time and money.

Establishing correlations between surface structure, film thickness and formulation

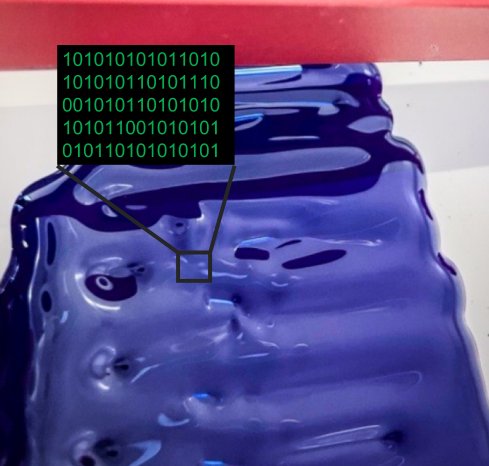

At EZD in Selb, a company of the SKZ Group, researchers are therefore working on a new development project to exploit the advantages of digitalization in the development of coatings, paints and inks. As part of the DigiLack project, correlations between surface structure, layer thickness and formulation are to be developed and material models created for the prediction and simulation of products. In particular, the influence of the grinding degree of the carbon black on the coating and ink properties of UV-curing systems will be investigated using in-process measurement methods.

More efficient development processes

The aim is to use digital simulations to make development processes more efficient in the future. This would save valuable resources and reduce the costs of numerous laboratory tests, which would be an important competitive advantage in the mid-sized industry and enable significant cost reductions. In addition, highly individual customer formulations would be easier to realize and complex requirements would be easier to implement. "We are very pleased to be able to use the equipment in our new laboratories in the first projects and to be able to contribute to increasing the efficiency of the production of paints, coatings and inks. Digitalization offers immense potential here - provided that good data models are used," says Dr. Felipe Wolff-Fabris, Site Manager at EZD.

The DigiLack project is funded by the Bavarian Ministry of Economic Affairs and is scheduled to run for two years.

The EZD is a facility of the SKZ Plastics Center and as an interdisciplinary and non-profit research and innovation center deals with the production and characterization of dispersions such as adhesives, resins, paints, coatings and elastomers. It was founded in 2014 in close cooperation with industry and with the support of the Free State of Bavaria. A high priority of the EZD is the transfer of scientific research to applied industry.