- Production starts two months earlier than agreed

- Hot strip mill extended by a further three finishing mill stands

The new hot mill is an essential element of the strategic expansion project of Henan Yirui, a subsidiary of the Henan Mingtai group, which is located in the city of Gongyi, Henan Province, China. This underlines Henan Yirui's trust in the expertise and experience of SMS group and its many successful references in the aluminum industry.

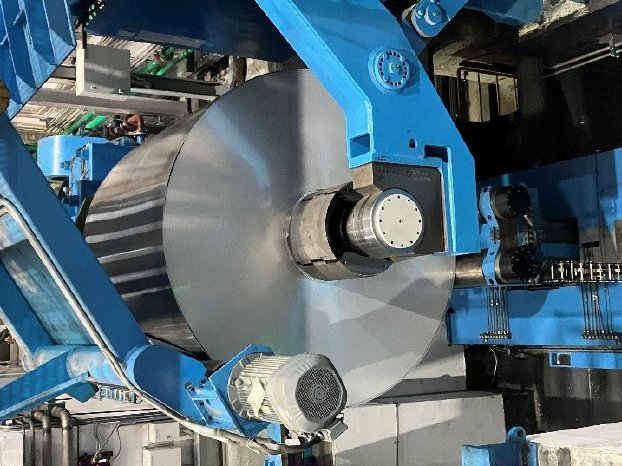

SMS group developed a solution to refurbish and integrate components from a secondhand 1+1 hot rolling mill, comprising a roughing mill and a single-stand finishing mill, into the 1+4 hot strip mill at the Gongyi site. SMS supplied the mechanical equipment, fluid systems, and X-Pact® electrical equipment and process automation. Three new finishing mill stands feature the cutting-edge CVC® technology for superior strip quality. The mill exit area includes a side-trimming shear of novel design, a down coiler unit, and an offline strip surface inspection station. The new hot strip mill can produce trimmed strips up to 2,150 millimeters wide.

Rolling of the first coil was originally scheduled for the first quarter of 2024. However, installation and commissioning times were significantly shortened thanks to the superior technology and the outstanding efforts, dedication and commitment of Henan Yirui and SMS group.

„A particular challenge was the seamless integration of secondhand equipment into a most modern four-stand tandem mill. We at Henan Yirui were convinced by SMS’ solution and ultimately impressed by its smooth implementation. The new SMS X-Pact® Level 2 process model controls the re-used roughing mill and the new finishing mill, thereby creating a fully integrated 1+4 aluminum hot strip mill,” says Liu Jie, General Manager of Henan Mingtai Aluminium.

The Chinese aluminum manufacturer is thus continuing its successful collaboration with SMS group, which began with the order for a six-high cold rolling mill and an AMOVA high-bay coil storage system.