The main goal of the upgrade is to cope with the future reduction of hot metal by replacing it with scrap in the charge. For this purpose, efficient injector technology is required. Furthermore, the upgrade will reduce operating costs and increase productivity.

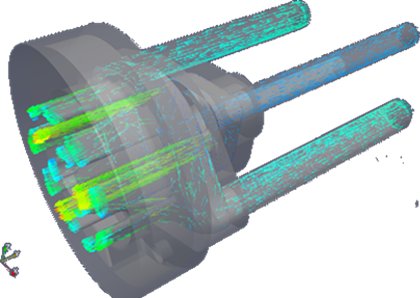

The injector design was developed using computational fluid dynamics (CFD). The new lightweight construction, ten percent lighter than previous version, is particularly easy to maintain.

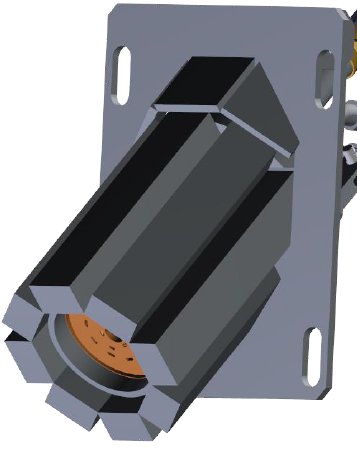

The SMS group ConSo R6 water-cooled copper boxes in monoblock design are not susceptible to cracking and effectively prevent water leakage. The integrated flashback detection system allows continuous monitoring of the ConSo R6 injector. The injector, which can be operated in burner or oxygen injector mode, additionally provides for automatic management of the melting profiles, ensuring excellent efficiency.

The SMS group scope of supply includes three ConSo R6 injectors, water-cooled copper boxes, the respective valve stations, an integrated flashback detection system as well as supervision of the erection and commissioning activities.