- The first aluminum facility for Steel Dynamics Inc. will produce sheet for cans, vehicles, and industrial applications and will boast a total annual capacity of 650,000 tons

- In entering the flat rolled aluminum products market, SDI is placing its trust in SMS group as a leading partner in the world of metals and in their long, shared history in the steel industry

- A considerable proportion of recycled aluminum scrap will be used as input material for manufacturing, thus making a significant contribution to sustainable aluminum production

SMS, the world market leader for aluminum hot and cold rolling mills, was selected for this project based on its technological expertise and the long-standing history shared by SMS and SDI. SMS group’s relationship with SDI stretches back to the mid-1990s when the two partners completed a large number of successful projects, the most recent being their newest steelmaking facility in Sinton, Texas.

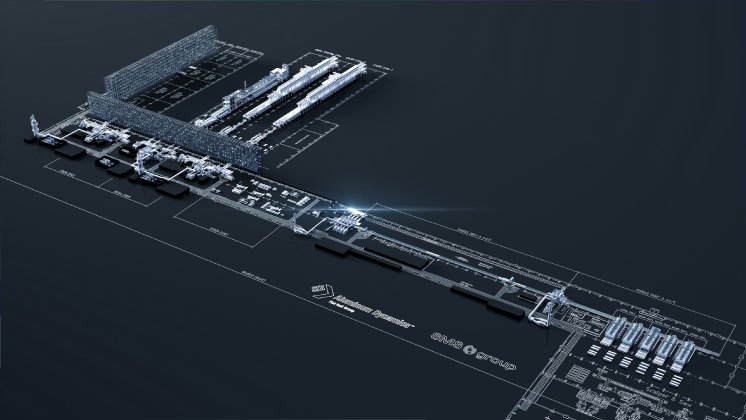

SMS group’s main order scope includes the hot strip mill, two tandem cold mills, a single-stand cold rolling mill, and two high-bay storage systems. All plants will be supplied from one source, including integrated SMS group solutions for the electrical and automation equipment. Thanks to this integrated approach, SMS is ensuring that the electrical and automation systems work in perfect harmony, helping to shorten the plant ramp-up time and increase the overall performance of the entire aluminum flat rolling mill.

The rolling mill complex is expected to start production in the first half of 2025.

The new facility will utilize a significant amount of aluminum scrap, provided by SDI’s metals recycling platform OmniSource. SDI intends to apply its experience and knowledge in the field of metals recycling in the production of flat rolled aluminum products. There is even the option of upgrading secondary aluminum scrap, as new sorting technologies are now available. This will help to raise production to a new level of efficiency and quality. Alongside the technological expertise, customers are set to benefit from SDI’s sustainable and customer-centric approach in the market for aluminum flat rolled products. With its new production complex, SDI plans to satisfy growing demand in the sustainable beverage can industry.

Scope of supply

1+4 Hot rolling mill

The hot strip mill will have a 1+4 configuration, comprising a roughing mill with attached edger and a four-stand finishing mill as the main items of equipment. The finishing mill consists of four rolling stands in the four-high, CVC®plus (continuously variable crown) design. Here, the transfer bar is rolled down to the desired strip thickness and coiled. The final strip thickness ranges from 1.8 millimeters to 7 millimeters. Plant flexibility and high rolled product quality are ensured by SMS group’s advanced rolling technology in conjunction with proven modules of the X-Pact® electrical and automation systems that are specially designed for aluminum production processes. This kind of configuration allows SDI to hot-roll all sorts of aluminum and aluminum alloys with the best surface quality and ideal thickness and profile tolerances, and trim them to a width of 2,450 millimeters.

Aluminum Dynamics, LLC can further process the aluminum hot strip in three downstream cold rolling mills, also part of SMS’ scope of supply.

Two-stand tandem cold mill (TCM #1)

SMS plans to deliver an ultra-modern two-stand aluminum tandem cold rolling mill to Aluminum Dynamics, LLC. The TCM is designed for combined reduction passes and processing EDT passes in the second stand of the cold mill to meet car manufacturers’ requirements. Both of the six-high rolling stands incorporate the proven CVC®plus technology in combination with the full range of actuators and technological controls. The equipment makes the TCM perfect for cold rolling automotive grades with a maximum strip width of up to 2,400 millimeters and a minimum strip thickness of 0.5 millimeters. Highly formable 5xxx-series alloys, which are mainly used for internal car body parts, and 6xxx-series alloys, primarily used for exposed external parts, can be processed in the same mill.

Single-stand cold rolling mill (CRM #1)

Also in the six-high CVC®plus design is the single-stand cold rolling mill (CRM1). The CRM is very flexible and capable of rolling a wide range of aluminum grades for can stock as well as for automotive applications. The maximum rollable strip width is 2,200 millimeters. Strip thicknesses range between 0.15 and 6 millimeters.

Two-stand tandem cold mill (TCM #2)

The second tandem cold mill (TCM #2) is designed for can stock rolling. The two stands are six-high and equipped with CVC®plus technology for roll shifting in combination with work and intermediate roll bending for an infinite roll gap setting range. The TCM #2 is fitted with almost every actuator and item of process equipment found in TCM #1. The maximum strip width to be processed is 2,200 millimeters, and the final gauge range to be achieved with this mill is between 0.15 and 3.5 millimeters.

Can coating line (CCL)

The can coating line (CCL) prepares cold rolled coils for aluminum can manufacturers and continuously processes in excess of 60,000 mtpa of coated aluminum coils covering 6,000 operating hours every year. All components in the line are designed by SMS group, including the entry coil cars, pay-off reels, stitching/coil joining, cleaning sections, accumulators, coaters, and tension reels. Of special interest is the flotation oven, which cures the coating while using jets of heated air to support the strip. This contactless curing provides the pristine coating surface required by the can manufacturing sector.

Two high-bay storage systems

AMOVA GmbH, an integrated business unit of SMS group, supplies intelligent, fully automated transport and storage systems. A process-specific high-bay storage system will provide the link between the hot mill and cold mills as well as the various process lines. The system is equipped with an integrated ventilation system for enhanced coil ventilation. The second scope of equipment to be supplied by AMOVA comprises a high-bay storage system for the finish-packed aluminum coils, for example in a large coil format. The new storage systems will be equipped with the warehouse management software developed by AMOVA, which, in addition to material tracking and visualization, offers numerous other features such as temperature-curve simulations – an essential function for monitoring and ensuring material quality for downstream aluminum strip processing.

Next generation X-Pact® electrical and automation system for aluminum rolling mills

SMS group is to provide Aluminum Dynamics, LLC with the sophisticated X-Pact® electric and automation system. This covers the full process chain from power distribution and drive equipment, measuring systems, sensors, and finally all the basic and process automation, including HMI and level 2 setup systems. The state-of-the-art control system with its newly developed software architecture is largely based on modern PLC system hardware and software, e.g. Siemens TIA. The intelligent linking of X-Pact® basic and process automation technologies with integrated technological solutions, such as X-Pact® Hot Start Assistant and X-Pact® Superior Control, opens up a wide range of possibilities for operating entire aluminum flat rolling mills in a highly dynamic and resource-efficient manner with less human intervention.

Like with every SMS project, the new automation system for Aluminum Dynamics, LLC will be fully installed, tested, and optimized during the X-Pact® Plug & Work integration test. Operating personnel from Aluminum Dynamics, LLC will be trained under realistic conditions with real-time process simulations that fully depict the interaction of the plant components and significantly shorten the time required for commissioning and optimization.

Link: bit.ly/3mAfizl