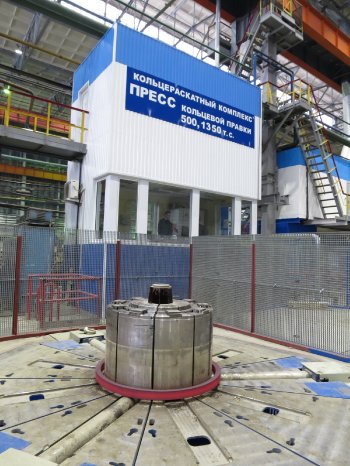

With the new ring rolling plant, consisting of a PL 8000-V3 ring blank press, RAW 400/200-3500/800 DM radial-axial ring rolling machine and two RKP 500 and RKP 1350 ring expanders, the Russian company is extending its product portfolio for the aerospace industry, at the same time increasing its competitiveness with this newly built production line. VSMPO is one of the world’s largest producers of forgings made of titanium alloys and a strategic partner of leading aircraft manufacturers such as Boeing and Airbus.

A special feature of the ring rolling line at VSMPO is the combination of the forging and the ring rolling process. With this technology developed by SMS group, VSMPO is able to produce rings with extremely complex inside and outside profiles. Furthermore, the material input is far lower than with the conventional forging process that the company has employed to date. With this new production line, VSMPO can manufacture titanium rings with a diameter of up to 3,500 millimeters and a height of up to 800 millimeters.

As systems supplier, SMS group supplied perfectly harmonized machines ensuring an optimized production process. Both this all-inclusive solution and the service on site convinced the customer.