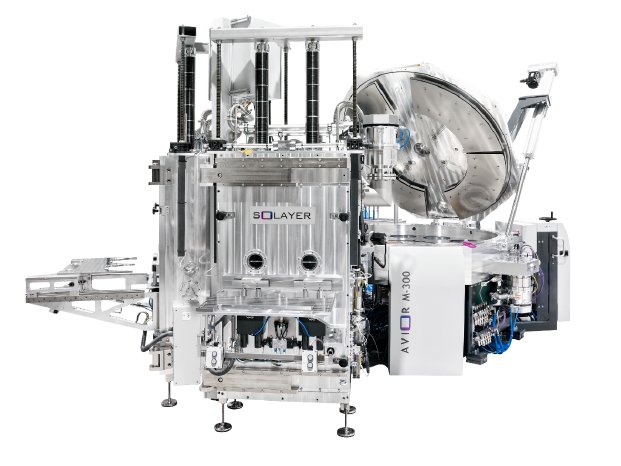

The new AVIOR M-300 is specifically designed to guarantee high throughput and reliable production of precision optics with outperforming film uniformity and characteristics.

Its’ unique combination of a Sputter-Up configuration with Dual Rotary Magnetrons offers unrivaled competitive benefits such as process stability, lowest particle count, minimal service time and cost of ownership.

Although the AVIOR M-300 can accommodate as much as 12 units of 300 mm substrates per run, its' flexibility in production is unrivaled, with carrier systems for various substrates sizes adaptations (such as 48 x 150 mm substrates).

Uninterrupted vacuum in the process chamber is assured with the AVIOR M-300 due to the load lock design. Remarkably, the dual-rotary sputter magnetrons with different materials (reservoirs ≈ 1,500cm3) serve several weeks of continuous production. The modular design which can incorporate as much as four materials and two plasma sources allows growth rates of about 10 nm/sec. This design capability offers a superior variety of dielectric, metallic and hybrid layers of multiple materials without the need for material change.

The AVIOR M-300 is equipped with an in-situ deposition growth control and has no need for calibration and test-runs even for stack designs of several hundred layers. Film thickness uniformity is guaranteed as well as prevention of deposited in-film defects. This results in stable and predictable deposition processes over weeks. Extremely dense, amorphous and shift free layers can be deposited.

With layer growth akin to ‘imaging’, the layers have almost no intrinsic roughness and a unique uniformity of down to 0.2 %.

SOLAYER’s AVIOR M-300 puts the Precision in Precision Optics.