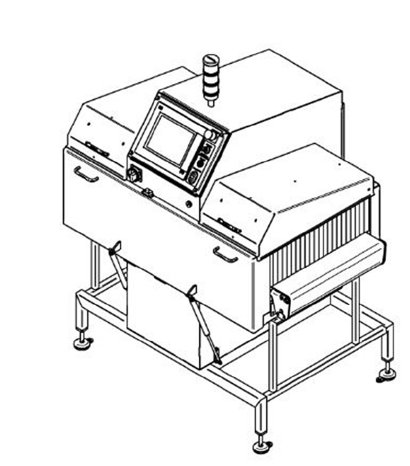

Digital X-ray technology as it is used in the RAYCON product inspection system is the most reliable method for the detection of contaminants in piece goods, and in addition to metal contaminations this technology also detects glass, ceramics, stones, raw bones, and several types of plastics. A particular advantage of the RAYCON X-ray system is its capability to also reliably inspect products that are packed in aluminium or in metallised foil. The performance range of the product inspection system in addition to contaminant detection also includes the simultaneous detection and separation of other product defects such as broken, deformed, or missing products, clumping, trapped air, as well as overweight and underweight.

Safety concerns with respect to the X-radiation that is used are dispelled by the design of the Sesotec systems. When properly used, X-ray scanners are absolutely safe for operators and for the inspected products.

Altogether the RAYCON product inspection system features all the well-known strong points of Sesotec systems, i.e. it uses highly sophisticated and reliable technology, and with modular conveyor belts it can be adapted to customer-specific requirements.

At the FachPack trade fair Sesotec for the first time presents the innovative advanced model of the familiar RAYCON inspection system, which in its development is based on the idea of hygienic design that is derived from the RAYCON H+W system (presented at the ANUGA 2015).

The main focus lies on easy access, maintenance, and replacement of belt and protective curtains. With the new system design the time required for cleaning and maintenance is considerably reduced.

In addition to the RAYCON product inspection system Sesotec at the FachPack 2015 of course also presents other metal separators and magnet systems that have proven themselves time and again in the food and packing industries. In the food industry all these systems help to optimise processes and minimise the loss of time and products.