X-ray-based product inspection systems are a possible alternative, but come with the disadvantage of being more expensive than metal detectors.

New technologies that combine high accuracy and affordability provide a promising solution to theses challenges.

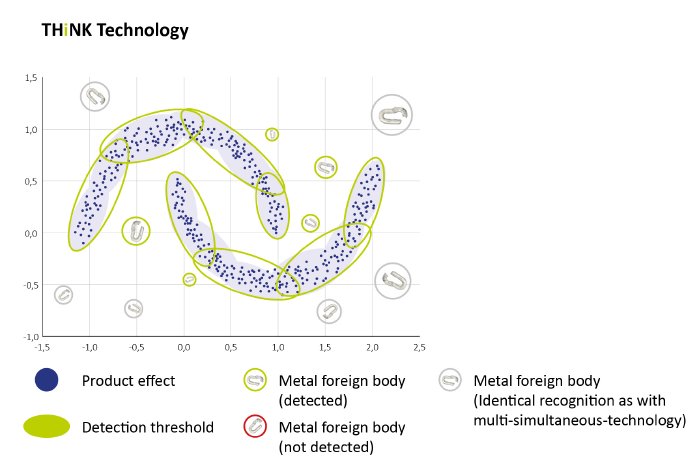

“THiNK,” the latest innovation from the Sesotec headquarters, is a metal detection system equipped with artificial intelligence. This technology makes it possible to virtually eliminate the interference caused by product effect.

HowdoesmetaldetectionwithTHiNKwork?

Like conventional metal detectors, THiNK uses multi-simultaneous technology to apply several frequencies to the product being inspected. Using AI technology, THiNK isolates the signals from product effect, creating additional detection thresholds. All signals that lie outside of these thresholds are identified as metallic contaminants. The detection sensitivity increases, but false rejects are reduced by means of more “intelligent” threshold calculation.

HowTHiNKmetaldetectionbenefitscustomers

Products with high or fluctuating levels of product effect (due, for example, to metallized packaging or storage in brine or water) can be more reliably inspected. False rejects, and the food waste they cause, are reduced. Food safety regulations and standards (e.g. IFS, BRCGS, M&S, etc.) can be reliably upheld. Compared with an x-ray inspection machine, a metal detector with THiNK is the more cost-effective option.

THiNKaboutit…

AI algorithms increase the reliability and precision with which contaminants are detected in the food manufacturing process. AI- nabled metal detectors can even efficiently inspect products packaged in metallized films. Food waste is reduced, food safety standards are upheld, resources are saved, and profit climbs as productivity rises. THiNK technology from Sesotec will be available as a licensed model starting in November 2020.

-

Watch our video “Metal Detection with Artificial Intelligence” here:

-

For more information visit: