The production of biopharmaceuticals often requires modifying the genetic heritage of cells and cultivating them in large-scale bioreactors during upstream production. The cells multiply and produce the protein of interest which is then extracted and purified. The first clinical trial was launched in 1989; however, the first real success came in 2000 in the United Kingdom.

A major breakthrough for public health, biotherapies are particularly useful for treating chronic diseases such as cancers. The techniques and technologies of biotherapy also play a central role in personalized medicine. As the recognition takes hold that a given medication, even in the same dose, does not suit every patient, demand for personalized medicine shows no sign of waning.

The field of bioproduction covers all the complex processes and biotechnologies that go into producing biopharmaceuticals under optimal sterile conditions. It goes without saying that quality control measures are critical here. Even as market forces pressure biopharmaceutical manufacturers to minimize production times and increase yields, safety and efficacy cannot be compromised.

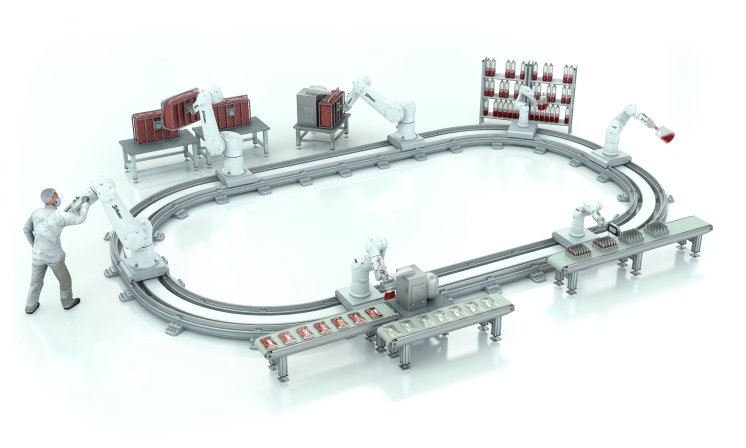

In the effort to meet such demands, automation is turning out to be a major ally. With the boom in biotherapies and ever-growing expectations for more personalized medicine, innovative robotic devices are poised to shape the future of bioproduction, making it more flexible, reliable and safer. As an early forerunner, the PUMA robot was used in the Cellmate cell culturing system for the production of biotech drugs in 1993.

Confidential upstream processes, new downstream trends

The process of producing generic drugs is commonly known. Yet the process of producing personalized medicine, notably ATMPs (advanced therapy medicinal products), remains closely guarded by pharmaceutical companies. This makes support for industrialization especially challenging. The opacity affects suppliers, who are left to generalize robotic applications as “management of the process of cell & gene therapy” without knowing exactly what the robots do.

In fact, there are numerous opportunities for robotic automation in personalized medicine and biotherapy production. By nature, personalized medicine is small batch production, or even unique batch production. Upstream, the specific “management of the process,” and downstream, the conditioning that finally gets closer to generic processes. But the push for machine builders to enable efficient, commercially sustainable small batch production has led to the need for a robotic arm that is more flexible and able to work within a small isolator.

The robot’s role is also expanding. It is no longer used for a single task, and while the workspace is limited, it is now placed at the center of the production, managing all operations. The trends of small batch equipment should follow the rest of the process to the logistics area in the future, with small batch inspection machines and small batch packaging machines.

Robots are proving their ability to adapt, provided they have a small footprint and the flexibility to handle any product. The use of robotic tool changers in pharmaceutical applications offers significant advantages here, as this technology greatly expands the tasks to be performed by a single robot.

Protecting production while scaling up

Producing a drug for a single patient has a high cost, and the pharma world is entering a new era of industrialization, with the main objective of scaling up by producing batches in parallel. To reach this goal, a few options have been identified.

One approach is to reduce the footprint of robotic cells and increase the number of cells in the production line. Another is to increase the size of the robots and limit scaled-up production only to the area around the robot, where the number of stations dedicated to “management of cell & gene therapy” would multiply.

In yet another scenario, robots are placed in a row, as in conventional industry production, or the same robot operates on a seventh axis as part of a linear transfer system, thus maximizing its capabilities. This solution is under development, since currently there is no mobile solution for pharma cleanroom areas. If, however, a cleanable and Grade A-compatible AGV or mobile robot comes to market, there is no doubt that it would quickly be integrated in this segment. This would provide a link between upstream and downstream processes – and open infinite possibilities for increasing production in Grade A/B environments.

When scaling up production and looking at the time of manufacturing that can reach several weeks, the potential loss of batches due to cross contamination rises as well. The risk of losing large quantities of product, and the staggering costs this would incur, justifies producing biotherapies in secured and monitored environments quite similar to the containment equipment used in historical flows. The impact of the revised GMP Annex 1 currently seen in generic drug manufacturing will push the industry overall to adopt more stringent contamination control strategies in terms of hygienic design and equipment cleanability. The manufacturers of ATMPs will follow the same rules to protect production.

It is clear that robots used in the production of personalized medicine, including biotherapies and ATMPs, need to align with GMP standards and use FDA-compliant materials, giving end users more confidence. For non-specialist companies like robotics, biotechnology is only at the beginning, and we can see that this parallel method of drug development will bring even more robots to the factory floor.