Robots in the pharmaceutical industry must meet strict criteria beyond the requirements of most other industries. The focus is on cleanability and compatibility with decontamination media and processes as defined by GMP grades. Stäubli Robotics brings leading-edge automation solutions to each area of production with robots engineered to meet the requirements of isolators, RABs, and freeze dryers in Grade A/B areas as well as less restricted Grade C/D areas.

ACHEMA attendees will have the opportunity to discover Stäubli’s complete pharma offering, comprised of three distinct robot ranges – the newest, accessPharma, for non-aseptic applications; Stericlean for aseptic applications; and Stericlean+ for use in isolators – covering the full spectrum of requirements. At Booth J72, Hall 3.1., Stäubli will exhibit three next-level pharma robots, representing each product range: a TX2-90 accessPharma, a TX2-60 Stericlean, and a TX2-60 Stericlean+.

Grade A/B to C/D: Product evolution for changing industry demands

Stäubli has been a partner to the pharmaceutical industry for decades. Its groundbreaking Stericlean series, launched in 2008, was the world’s first robot designed to operate in areas with rigorous cleaning procedures. They have since been deployed in pharmaceutical and biotech labs and production facilities worldwide, where they bring new levels of efficiency to material handling, fill-finish, and many other applications.

The current era, defined by new market challenges and stricter regulations such as the revised GMP Annex 1, requires solutions that can stand up to heightened regulatory scrutiny while elevating efficiency and increasing output. Building on the long success of the acclaimed Stericlean, Stäubli worked with OEMs, system integrators, and customers in the pharmaceutical space to expand and adapt its robots to handle more applications and meet changing compliance and commercial needs. The result is Stericlean+, which debuted in 2022 with the flagship TX2-60.

Stericlean+ is a breakthrough in the automation of highly aseptic processes, featuring higher cleanability, a new FDA-compliant surface coating and joint sealings, and other enhanced hygienic design features aimed at delivering unprecedented levels of product and patient safety. The entire outer surface is capable of withstanding intensive cleaning and decontamination with VHP (H2O2) in isolators.

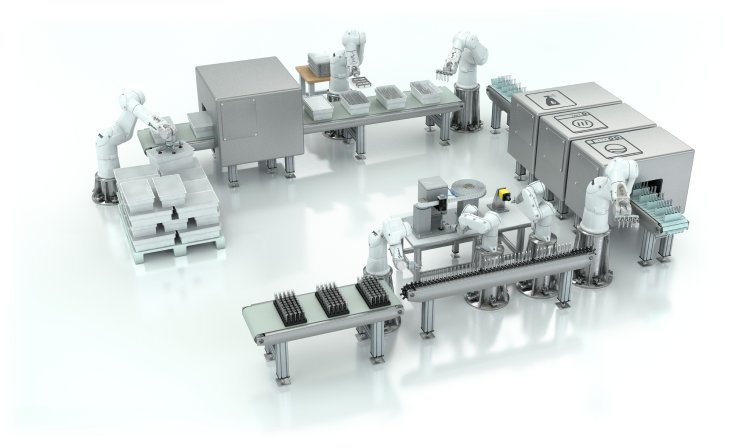

Together, Stericlean and Stericlean+ cover all requirements in Grade A/B production areas, meeting the highest hygiene and cleanliness standards in isolators, RABs, freeze dryers, and autoclaves. They are also used in cell & gene therapy (CGT), biotherapy, API research and production, lab automation, auxiliary processes, and other areas within pharmaceuticals.

Bringing optimal automation to the Grade C environment

The newest pharma offering from Stäubli, accessPharma, focuses on the Grade C environment, coming full circle with fast, reliable automation solutions for non-aseptic areas. The accessPharma series is designed for inspection and secondary packaging applications in Grade C/D areas, where cleaning is generally handled with isopropyl alcohol or ethanol alcoholic wipes. The robots feature a new isopropyl alcohol- and ethanol-resistant coating, as well as hygienic screws.

Automation upgrades in Grade C areas can help organizations cope with labor shortages and relieve workers of the physical demands of loading and unloading machines. They also support regulatory compliance and help ensure consistent workflow and throughput.

Stericlean+ demos and exhibits bring aseptic automation upgrades to life

Minimizing human intervention is always a major theme in pharmaceutical industry automation. The revised Annex 1 specifically emphasizes the need to reduce human intervention in aseptic processes and increase automation to lower the risk of contamination while scaling production.

Automation and robots have long been the norm in Grade A/B areas, where product containers remain open, and the risk of contamination is high. However, open systems that allow manual fault intervention via glove ports continue to pose risks. Annex 1 discourages the use of glove ports, accelerating the trend toward closed automated systems with gloveless isolators. In such systems, the same robots that perform process tasks can handle fault interventions with the use of telemanipulation, thereby eliminating the risks.

In an interactive exhibit at ACHEMA, attendees will have the opportunity to test Stäubli’s telemanipulation functionality hands-on, moving a TX2-60 Stericlean+ robot with an optional hollow wrist using a joystick rather than gloved hands – a technological advancement that promises to propel the industry forward in its evolution.

Automating the gap between fill-finish and freeze dryer

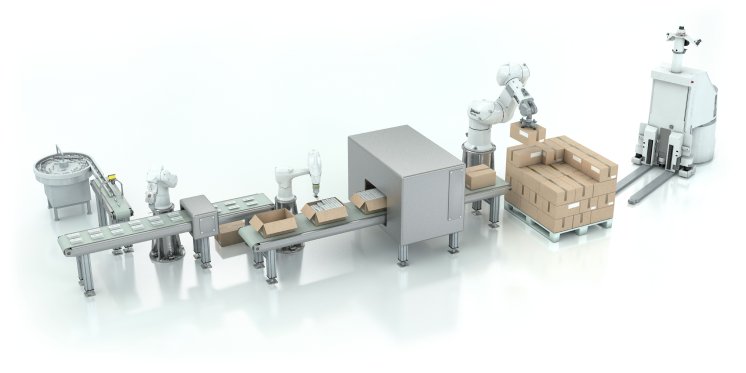

A look at the set-up of pharmaceutical production lines, particularly fill-finish machines and freeze dryers, can reveal key trends in automation. In new plants, these stations are usually arranged close to one another. This is not always the case at existing plants that require automation upgrades; therefore, automating transportation from the end of the fill-finish line to the freeze dryer is currently a major focus of automation upgrades.

Traditionally, product containers are moved between filling and freeze drying stations either by conveyors or humans. But a more efficient and safer alternative is on the horizon: automated guided vehicles (AGVs) adapted to the aseptic requirements of Grade A/B environments. Serving as a link between these cells, a mobile solution could be the key to meeting aseptic process requirements while increasing production.

According to Rudolf M. Weiss, Global Head of Life Sciences & Food at Stäubli Robotics, “We continuously develop robotic solutions for all applications and cleanroom levels in the life science sector, but the spotlight will be on hygienic design mobile robots for highly demanding mobile applications in Grade A/B environments, where rigorous cleaning requirements apply.”

Stäubli’s pharma robots are already a major asset on fill-finish lines. ACHEMA attendees can witness this for themselves at Stäubli’s freeze dryer loading/unloading demo cell, developed in partnership with Spanish company Telstar, a specialist in pharmaceutical process equipment. The demo features a stationary Grade A-compliant TX2-90 Stericlean+ robot loading trays into a “pizza door” freeze dryer and handling auxiliary tasks such as picking up clips and linking the trays to each other.