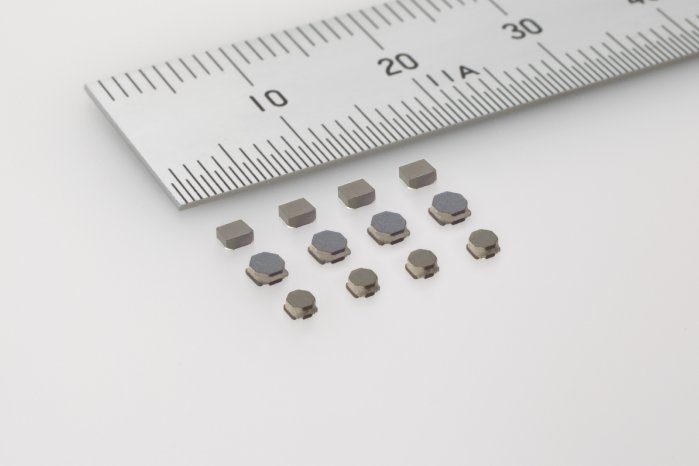

commencement of production of newly enhanced low profile products for its metal power inductors MCOILTM. These products include 1.6mm square metal core SMD power inductor MDKK1616 (1.64 x 1.64 x 1.0mm), a 2.0mm square metal core SMD power inductor MDKK2020 (2.0 x 2.0 x 1.0mm), and the EIA0806 size metal core wire-wound chip power inductor MKK2016 (2.0 x 1.6 x 1.0mm). The height value indicated is the maximum value for each of the products, which achieves a thickness of just 1.0mm.

These products are power inductors for choke coil applications in the power supply circuits of digital devices, such as small mobile devices including smartphones and tablet PCs, as well as SSDs, which are becoming further miniaturized and have an increasingly low profile with an ever-increasing performance requirement. By combining TAIYO YUDEN’s own metallic magnetic materials and advanced process technology, we have added to our product line-up of low profile products which meet the rigorous demands of the market while

maintaining industry-leading DC bias characteristics.

As a response to the surge in demand for these products preparation for production from December 2012 onward is now underway at the company’s Nakanojo plant (Nakanojomachi, Agatsuma-gun, Gunma prefecture). The planned production rate is 170 million units per month for the entire series of metal power inductors MCOILTM.

Technology Background

To achieve both high performance and high efficiency, processors in mobile devices, as typified by smartphones, continue to have increasingly high speed drives and are increasingly multi-core. In such processors, power supply circuits must be installed that can support large currents in each core. Our designs achieve this while also achieving miniaturization and a decreased thickness. And, there is a growing requirement for miniaturizing and decreasing the profile of the components employed. There is an inherent problem with power inductors which use conventional ferrite materials where the DC bias characteristic drops with miniaturization, which no longer allows a large current to flow. And, the effect of noise caused by the leakage flux generated

from the power inductor on the surroundings has also become an obstacle to high density packaging.

To meet these critical challenges, TAIYO YUDEN has developed a new molding

process for metallic magnetic materials which can significantly improve the DC bias characteristics. TAIYO YUDEN has also developed the process technology fostered through the NR series of products. These products have a proven track record as SMD power choke coils. In addition, TAIYO YUDEN has developed metal power inductors MCOILTM, which reduce leakage flux and provide for both a large current and miniaturization with a low profile.

In the future, we will concentrate on the development of compact, low profile super high-end products, which will meet market needs for smartphones and other such mobile devices. We will push forward with the product launch of other metal power inductors MCOILTM as well.

* MCOIL is a registered trademark or a trademark of TAIYO YUDEN CO., LTD. in Japan and other countries.

■ Applications

Choke coil applications for the power supply circuits in digital devices that include small mobile devices, such as smartphones and tablet PCs, as well as SSDs.