The first implementation and testimonial was successfully executed for ABB, a company located in Switzerland. In the meantime two additional (Smart Pad Printing) process solutions are under construction.

An exemplary Process Solution of this kind will be shown to the public for the first time at the upcoming "LASYS" show in Stuttgart, June 12-14, 2012. Please visit us in Hall 4, Booth 4D57.

We will show you how you can print or mark your products with variable and static data records, and at the same time achieve uninterrupted quality management, as there is no manual allocation of the work-pieces and image required. This completes the manufacturing process for all manufacturers of components, which cannot be coded or printed with traditional marking techniques.

Procedure Example:

OPTION 1:

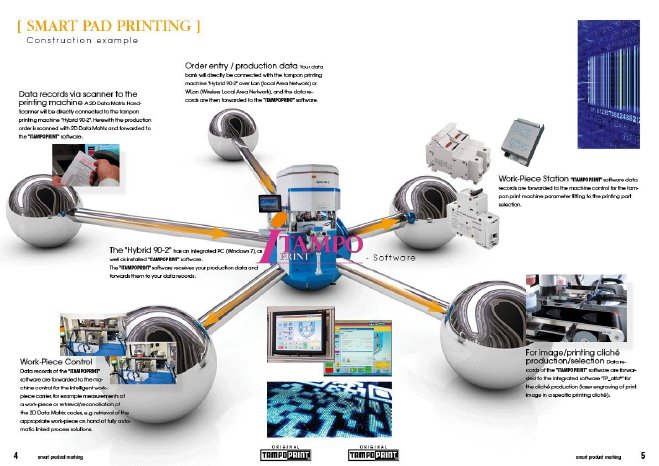

Your Data Bank (operating system) will directly be connected with the Tampon Printing Machine "Hybrid 90-2" over Lan (Local Area Network) or WLan (Wireless Local Area Network), and the data records are then forwarded to the "iTAMPOPRINT" Software.

OPTION 2:

A 2D Data Matrix Hand-Scanner will be directly connected to the Tampon Printing Machine "Hybrid 90-2". Herewith the production order is scanned with 2D Data Matrix and forwarded to the "iTAMPOPRINT" Software.

The "Hybrid 90-2" has an integrated PC (Windows7), as well as installed "iTAMPOPRINT" Software. The "iTAMPOPRINT" Software receives your production data and forwards them to your data records:

A) For image/printing cliché production/-selection to the integrated Software "TP_alfa®" for the cliché production components (laser engraving of print image in a specific printing cliché)

B) Work-Piece Selection to the machine control for the tampon print machine parameter fitting to the printing part selection.

C) Work-Piece Control to the machine control for the intelligent work-piece carrier, for example measurements of a work-piece or retrieval/reconciliation of the 2D Data Matrix codes, e.g. retrieval of the appropriate work-piece on hand of fully automatic linked process solutions.

The "Hybrid 90-2" with 2 Printing Units makes many variables possible:

Option 1:

1st Print Unit with static data, 2nd Print unit with variable data 1st and 2nd Print Unit with different colour shades(suitable for components with different surface colour theme)

Option 2:

1st and 2nd Print Unit with different ink types (suitable for components made of different materials, e.g. with different surface properties)

The same process can alternatively be implemented with the more reasonable printing machine "MC-40". Here a disk cliché contains 12 circular arranged motives, which will be re-called respectively. In this case the PC would be arranged externally.

Trade Marks of TAMPOPRINT® AG: ALFALAS®, TAMPOPRINT®, ClipLock®, record®