Warming the "wheel" using gas flames at a pre-treatment station, part drying units and post-treatment can lead to register inaccuracies and feed problems. But room temperatures also have a significant influence on the print quality. It can cause increased evaporation of solvents or faulty print image transfer.

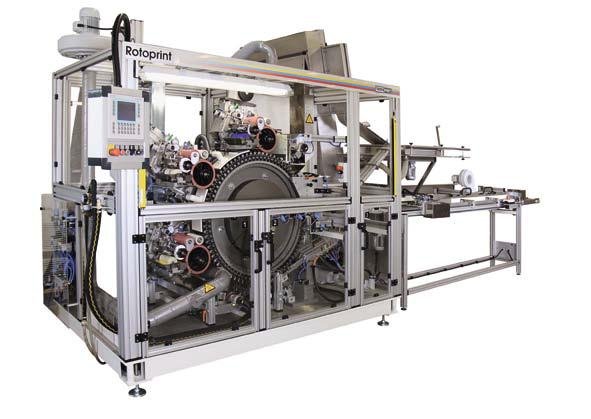

Years of practical experience have enabled TAMPOPRINT® to be the first to bring this unique solution to the market: the watercooled part transport unit including jig carrier, known in short as the "wheel". To complete the picture, a completely re-engineered rotary printing unit, the "RTI 21-150" makes its appearance as the successor to the "RTI 2000", which has put in stalwart service over many years.

The "water-cooled wheel" option can be selected for 1- and 2-lane "Rotoprint" fully automated systems.

The "water-cooled wheel" is standard equipment with 3-lane "Rotoprint" fully automated systems.

Water feed and drain-off is done through the existing cooling circuit in your injection moulding machine or through an optional water cooler.

Visit us at the FAKUMA 2012 in Friedrichshafen, Hall A1, Booth 1233. Here you will receive expert advice. Technical details or a personal appointment can be requested by emailing to mailto:messe@tampoprint.de. At all times we offer live demonstrations of our machines in progress. We invite you for a personal visit to our company headquarters or to co-ordinate a video conference on a desired appointment date.

Trademarks of TAMPOPRINT® AG: ALFALAS®, TAMPOPRINT®, ClipLock®, record®