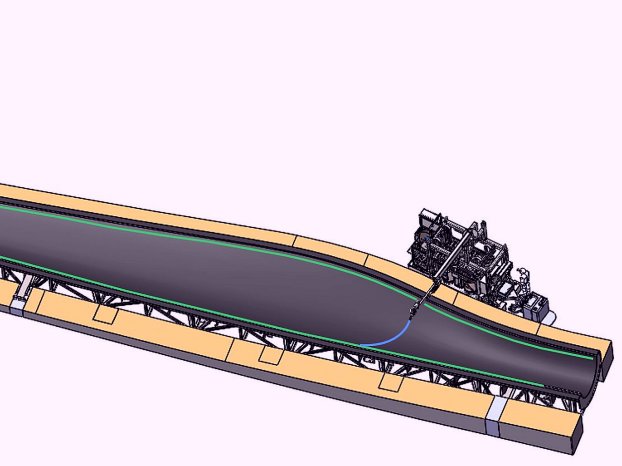

In the production of rotor blades for wind turbines, large quantities of synthetic resins are used for the bonding of the up to 85-meterlong blade shells alone. For almost three decades, TARTLER GROUP has been equipping well-known manufacturers in the industry with the modular multi- component systems of its Nodopox series for the largely automated dosing, mixing and application of mostly high viscosity pastes. Six years ago, the company started developing vacuum-based degassing stations that enabled rotor blade producers to make their synthetic resin processing much more material- and cost-efficient. The new TAVA 200 F vacuum systems are now setting technological standards in terms of sustainable process optimization. This is because the complete, bubble-free filling and transfer of the synthetic resins into lidded drums paves the way for safe material handling and the implementation of resource-saving and cost-effective preparation and recycling processes.

Degassing station reduces material loss

For a long time, a constant source of annoyance in rotor blade production was that large quantities of homogeneous resin residues – from opened drums or from the preparation phase – could not be reused or recycled. They had to be removed and disposed of, which had a negative impact on costs and ran counter to all approaches to the sustainable use of materials. Several on-site analyses by TARTLER engineers revealed, for example, that even when drums were emptied properly and in accordance with the operating instructions, up to 14 kg of material still remained in the inliners – clearly visible after drum changes in the dosing and mixing systems. What’s more, testing and quality controls lead to several kilograms of leftover material – per rotor blade. Added to that, residual quantities from flushing, surpluses and other ancillary work also create waste. Until now, however, it has not been possible to simply return the residual material produced at the various points to the production process. The reason: Air pockets, air bubbles and moisture are created when filling the lidded drums. If this „disturbing air“ were to enter the pump of the dosing and mixing system during removal, transfer and dosing of the material, the manufacturing process would be massively disrupted. Process interruptions would be required to flush the complete system (several times) with material for it to work air-free and properly again. All this would lead to considerable material losses and further costs, since prefabricated components would have to be restored and upstream processes would have to be cleaned at great expense.

Returning material residues

With the TAVA 200 F degassing station, the TARTLER GROUP offers a way out of this dilemma. With this system, both liquid and paste-like residues can be filled into lidded drums without „disturbing air“ and then safely reintroduced into the processing cycle with minimal loss. Significant savings in material purchasing can be achieved in this way. By using the TAVA 200 F, a leading wind turbine manufacturer was recently able to reduce its synthetic resin consumption by approx. 28 tonnes of synthetic resin paste per year, thus considerably reducing the overall costs in its rotor blade production. In this way, the system also counteracts waste and makes a considerable contribution to the conservation of resources. It also improves the environmental balance of the company’s value chain and reduces its ecological footprint.

Process integrated circuit

The rotor blade manufacturer in question optimized the blade bonding process by integrating a TAVA 200 F into its synthetic resin processing resin processing. Here the collected material residues are filled and decanted into standard clamping lid drums, degassed and freed from any interfering air. Once a drum is completely filled with reconditioned material, it can be used again in a 2K Nodopox system (or similar machine) for dosing, mixing and applying the synthetic resin adhesive. In this way, the manufacturer can reuse almost all homogeneous material residues. According to TARTLER‘ s calculations, the return on investment can be achieved after less than 24 months. Positive side effect: As the amount of waste decreases, the costs of disposal are also reduced.

Airfree on YouTube

The TAVA 200 F is configured and delivered by SOMATA, a subsidiary of the TARTLER GROUP. The degassing station is offered as standard for the air-free filling and transfer of 200- and 50-liter drums, but can also be adapted to other container sizes on request. It consists of a device for clamping and stabilizing the drum, a special combination attachment for synchronized vacuum generation and filling, a vacuum pump and a control system with touch screen. All components are installed on a base with a drum centering plate and are accessible from all sides. While the loading of the station, positioning of empty drum and closing of the clamping device can be done manually, the evacuation of the drum and almost simultaneous filling of the material are fully automated. After a few minutes, a drum is filled without air and is ready for use in production. This process is clearly illustrated in a video on the SOMATA YouTube channel

SAFE AND RESOURCE-SAVING PROCESSES

In addition to the TAVA 200 F, offers the TARTLER GROUP three further system solutions for the degassing of high and low viscosity materials. These are the drum changing system TAVA D and the evacuation system T-EVAC in their offline and inline configuration. They are all based on vacuum technology and are used to remove interfering air and moisture in the handling of pasty and low-viscosity media – both during filling and feeding into the processing plant. As shown by the example of the TAVA 200 F, the systems can also be used for production-integrated reconditioning of material residues, for targeted waste reduction and for the realization of internal material cycles.