One of the key issues in hydrogen-based flight is the storage of hydrogen. Due to the lower volumetric energy density of hydrogen (compared to kerosene), this takes up a lot of space and can add to system weight. The available installation space must therefore be optimally utilized, which means that the individual subsystems such as support structures, control structures and safety systems interact with each other to an exceptionally high degree. This leads to demanding, interactive development processes. The planned work in the SaxonHy project will take the example of an H2 pressure tank assembly integrated into the center wing of a small aircraft. A system model will be developed for this assembly as a basis for tank design and integration. Considering the specific requirements, an exemplary design of the H2 pressure tank assembly is aimed at. It will be investigated whether a tank system can be realized without a plastic liner (type 5 tank) to increase the gravimetric storage density. Finally, the designed pressure tank is to be manufactured for aviation and tested under pressure and maneuvering loads in specially developed system tests so that a certification concept for hydrogen tanks can be developed as part of SaxonHy.

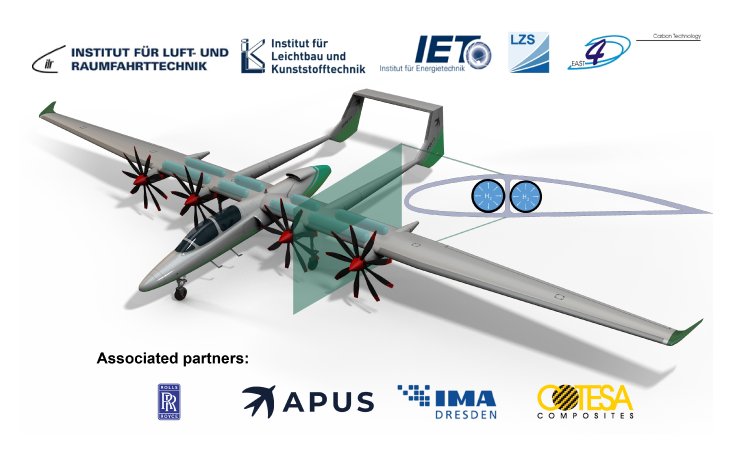

Project SaxonHy: "System-integrated H2 pressure tank assemblies for general aviation and feeder aircraft"

Funding

Supported by: European Regional Development Fund (EFRE) in Saxony, Technology Funding, Research and development - project funding (R&D project funding), Project number: 100558500

Managed by: Sächsische AufbauBank (SAB)

Period: 01.12.2021 - 31.05.2023

Project management at the ILK: Prof. Dr.-Ing. habil. Maik Gude (Chair of Lightweight Design and Structural Assessment)

Project partners

Consortium leadership: Leichtbau-Zentrum Sachsen GmbH

Institute of Lightweight Engineering and Polymer Technology (ILK) of the TU Dresden

Institute of Aerospace Engineering (ILR) of the TU Dresden

Institute of Power Engineering (IET) of the TU Dresden

EAST-4D Carbon Technology GmbH

Associated project partners:

Rolls-Royce Deutschland Ltd. & Co.KG

APUS – Aeronautical Engineering GmbH

COTESA GmbH

IMA Materialforschung und Anwendungstechnik GmbH